Understanding the Functions of Controlled Pressure Drilling Systems in Drilling Equipment

When it comes to drilling equipment, the use of managed controlled pressure drilling (MCPD) systems has revolutionized the industry by providing a more efficient and safer approach to drilling operations. These systems are designed to precisely control pressure within the wellbore to better manage downhole conditions and ultimately improve the overall drilling process.

So, how does a controlled pressure drilling system work in a drilling rig? Let’s delve into the capabilities of these systems to better understand their operation.

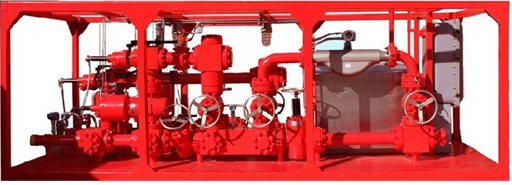

Controlled pressure drilling systems are equipped with advanced technologies and components that work together to maintain optimal pressure conditions within the wellbore. One of the key components of these systems is controlled pressure drilling equipment, which includes various tools such as pressure control valves, chokes and sensors. These tools are critical for monitoring and adjusting pressure levels during drilling.

The capabilities of a managed controlled pressure drilling system begin with real-time monitoring of downhole pressure using sensors and instrumentation. These sensors continuously collect data on pressure conditions within the wellbore, providing critical information to drilling operators. Based on this data, the system can automatically adjust the pressure control valve and throttle to maintain the desired pressure level.

In addition, controlled pressure drilling systems utilize advanced software and algorithms to analyze collected data and make predictive adjustments to pressure control mechanisms. This proactive approach enables the system to predict pressure fluctuations and make preemptive changes to prevent any potential problems during drilling.

In addition to pressure control, Well Control Equipment controlled pressure drilling systems also have controlled pressure cementing capabilities. This feature allows for precise control of the cementing process, ensuring cement is accurately and efficiently placed within the wellbore. By maintaining required pressure conditions during the cementing process, the system helps enhance the integrity of the wellbore and minimizes the risk of cementing-related problems.

Overall, the functionality of a controlled pressure drilling system in a drilling rig focuses on the precise management of downhole pressure. By leveraging advanced technology, real-time monitoring and predictive control capabilities, these systems provide a more efficient and safer approach to drilling operations.

In summary, controlled pressure drilling systems play a vital role in improving the performance and safety of drilling equipment. These systems maintain optimal pressure conditions, helping to increase drilling efficiency, reduce downtime and enhance wellbore integrity. As the industry continues to evolve, the adoption of controlled pressure drilling systems is expected to become increasingly common, further shaping the future of drilling operations.