Revealing the mechanics of TCI drill bits in drilling equipment

When it comes to drilling equipment, the efficiency and effectiveness of the drilling process largely depends on the type of drill bit used. TCI (tungsten carbide insert) drill bits are among the most advanced and widely used in the industry. TCI drill bits are known for their superior performance in a variety of drilling applications, but how exactly do they work?

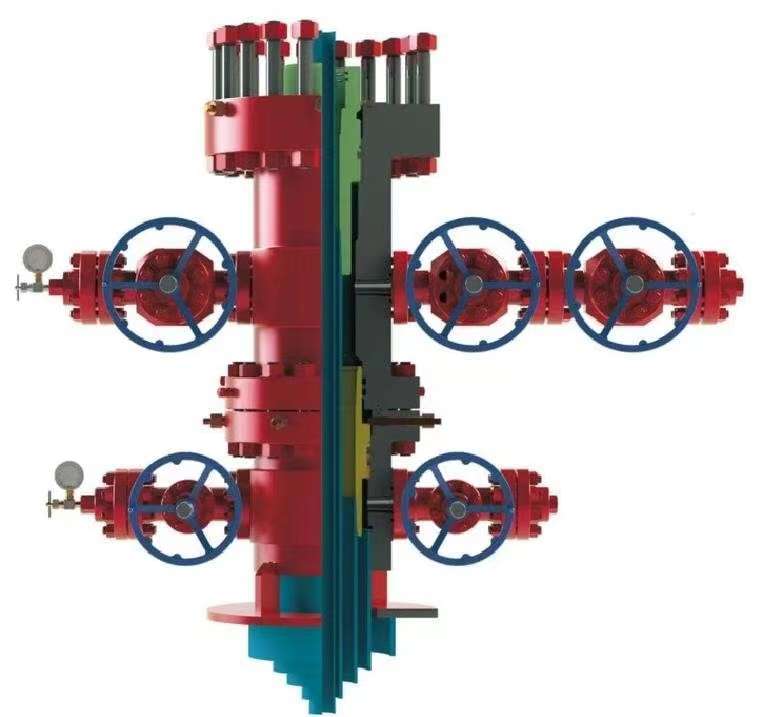

TCI drill bits feature a cutting construction design that incorporates tungsten carbide inserts into the drill’s steel body. These blades are carefully positioned and are the key components responsible for the cutting action of the drill. Tungsten carbide is known for its hardness and wear resistance, allowing TCI bits to withstand the extreme forces and wear encountered during drilling.

The mechanics of TCI drill bits involve the interaction between the tungsten carbide insert and the formation being drilled. As the drill bit rotates, the TCI blade comes into contact with the rock formation, initiating the cutting action. The hardness of tungsten carbide allows the blades to effectively shear and break rock to create drill holes.

One of the main advantages of TCI drills is their ability to maintain cutting efficiency over time. This is due to the wear-resistant properties of tungsten carbide, which allows the blade to maintain its sharpness and cutting ability even in challenging drilling conditions. As a result, TCI drill bits are able to achieve higher penetration rates and overall improved performance compared to conventional roller cone drill bits.

Additionally, TCI drill bits are designed to handle a variety of formations, including hard and abrasive rock. The strategic placement of tungsten carbide inserts optimizes cutting of different rock types, making TCI drill bits a versatile choice for a variety of drilling applications.

In addition to their cutting capabilities, TCI drill bits are engineered to efficiently eject drill chips from the drilled hole. This is achieved through the design of the drill bit’s hydraulic capabilities, which help clear debris and maintain the integrity of the drilling process.

The success of TCI drill bits in drilling equipment can also be attributed to continued advances in drill bit design and engineering. Manufacturers continue to innovate to improve the performance and durability of TCI drill bits, ensuring they meet the ever-changing needs of the drilling industry.

In summary, TCI drill bits play a vital role in the efficiency and success of drilling operations. Its innovative design incorporates tungsten carbide inserts, allowing it to provide superior cutting performance, wear resistance and versatility in a variety of formations. As drilling technology continues to evolve, TCI drill bits remain at the forefront, driving advancements in drilling equipment.