Understanding the Function of a Choke Manifold in a Well Control System

In the oil and gas industry, well control is critical to ensuring the safety and efficiency of drilling operations. An important component of the well control system is the choke manifold, which plays a vital role in regulating fluid flow in the well. Understanding how a choke manifold works is critical to maintaining well control and preventing potential hazards.

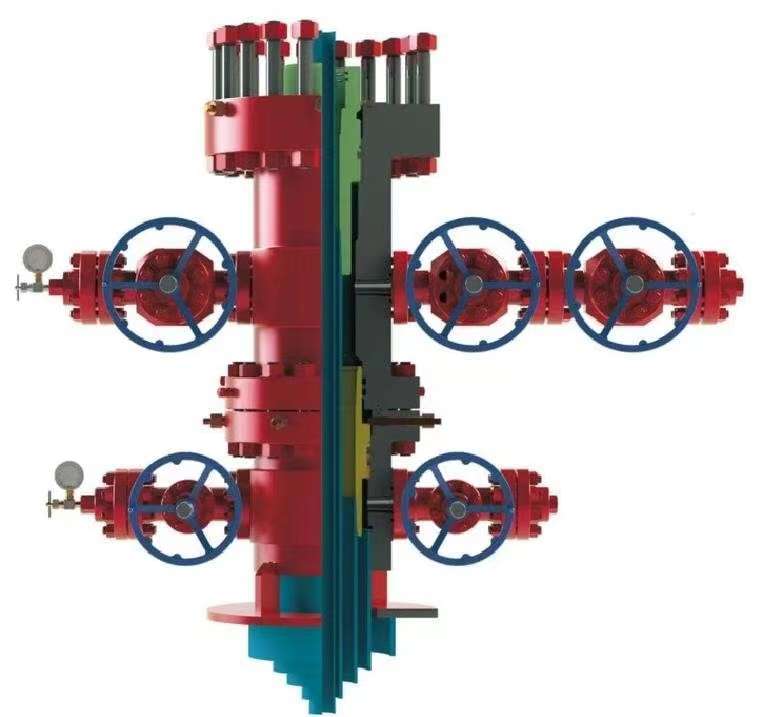

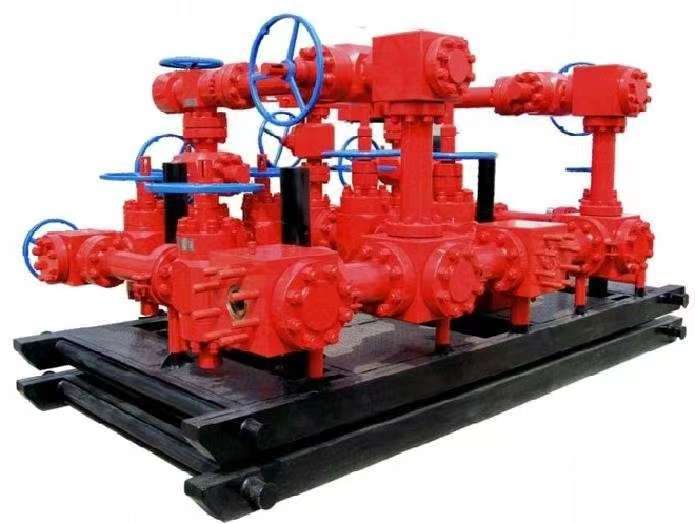

The choke manifold is a key component of pressure control equipment in drilling operations. It is designed to control the flow of fluids in a well, especially during well control situations such as kicks, blowouts, or other pressure-related issues. A choke manifold is composed of various components, including valves, chokes, and pipes, all of which work together to manage the pressure and flow of fluids from the well.

The primary function of a choke manifold is to regulate the pressure and flow of fluid from the wellbore. During drilling operations, the wellbore is filled with a mixture of drilling fluid, oil, natural gas, and other substances. When pressure inside a wellbore is too high, it can cause a kick or blowout, posing significant risks to drillers and the environment. Throttle manifolds help prevent such events from occurring by controlling fluid flow and maintaining required pressure levels.

A choke manifold restricts the flow of fluid from a well through the use of a series of valves and chokes. When a kick or blowout occurs, the choke manifold is activated, diverting fluid from the drilling rig into a designated containment system. This process helps reduce pressure within the wellbore and prevents any potentially dangerous escalation.

One of the key components of a choke manifold is the choke itself, which is a valve specifically designed to restrict fluid flow. Throttle valves come in a variety of designs and sizes to precisely control flow and pressure levels. By adjusting choke valve settings, operators can effectively manage fluid flow in the well and maintain safe operating conditions.

In addition to controlling fluid flow, choke manifolds serve as critical components for well testing and monitoring. During well control operations, choke manifolds can collect valuable data on the composition and behavior of fluids coming from the well. This information is critical to making informed decisions about well conditions and implementing appropriate controls.

Overall, the choke manifold is an important component of the well control system, providing the necessary means to regulate fluid flow and maintain safe operating conditions. By understanding how a choke manifold works, drilling operators can effectively manage pressure-related issues and ensure the safety and efficiency of operations. Choke manifolds play a critical role in well control and therefore remain an essential component of the oil and gas industry's commitment to safe and responsible drilling practices.