Understanding the Function of Mud Gas Separators in Oil and Gas Drilling

In oil and gas drilling operations, safety and efficiency are paramount. One key piece of equipment that plays an important role in ensuring safety and efficiency is the Mud Gas Separator (MGS). But how does a mud gas separator work, and why is it critical in drilling operations?

To understand the function of a mud gas separator, you must first grasp the concept of gas drilling. In gas drilling, drilling fluid, also called mud, is used to lubricate the drill bit, carry cuttings to the surface and maintain wellbore pressure. However, during drilling, natural gas and other hydrocarbons may also be released from the formation and mix with the drilling fluid. This can lead to the formation of gas inflows that, if not controlled, can lead to dangerous and potentially catastrophic blowouts.

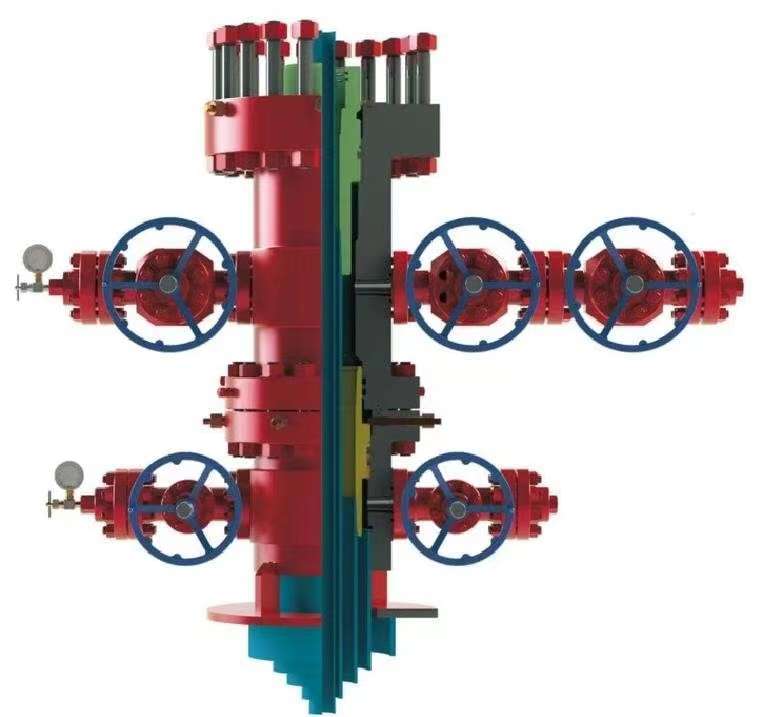

This is where a mud gas separator comes into play. The primary function of a mud gas separator is to separate and remove the drilling fluid from the drilling fluid before it reaches the surface. MGS achieves this through a combination of gravity and mechanical separation processes.

Mud gas separators are typically vertical vessels that allow drilling fluid and gas to enter from the top. As the mixture enters the container, gravity causes the heavier drilling fluid to settle at the bottom while the lighter gases rise to the top. The container is equipped with internal baffles and a mist removal device to help enhance the separation process. The separated gas is then vented to a safe location away from the drilling rig, while the drilling fluid continues its return to the mud system.

One of the key components of a mud gas separator is the exhaust line, which is designed to carry separated gas safely away from the rig. This is essential to prevent gas buildup around the rig, reducing the risk of fire or explosion.

In addition to its main function of gas separation, the mud gas separator also serves as a safety device. In the event of a kick, an influx of formation fluids into the wellbore, MGS can provide a way to divert gas away from the rig, thereby reducing the risk of a blowout. This is accomplished by quickly and efficiently separating gas from the drilling fluid, helping to maintain well control and prevent potential hazards.

In summary, mud gas separators are critical components in oil and gas drilling operations. Its ability to effectively separate gas from drilling fluids, coupled with its enhanced safety by diverting gas away from the rig, makes it an indispensable piece of equipment. Understanding how mud gas separators work is critical to ensuring the safety and success of drilling operations in the oil and gas industry.