Kill manifold of well control equipment

product Description

The product is necessary for controlling kick and implementing pressure control technology of oil and gas well.

When the wellhead is fully sealed with blind ram, heavy mud is forced into the wellbore through the kill manifold to implement well killing operation; when blowout occurs, clean water is forced into the wellbore through the kill manifold to prevent combustion and fire; when the blowout is on fire, fire extinguishing agent is forced into the wellbore through the kill manifold, it can help put out the fire.

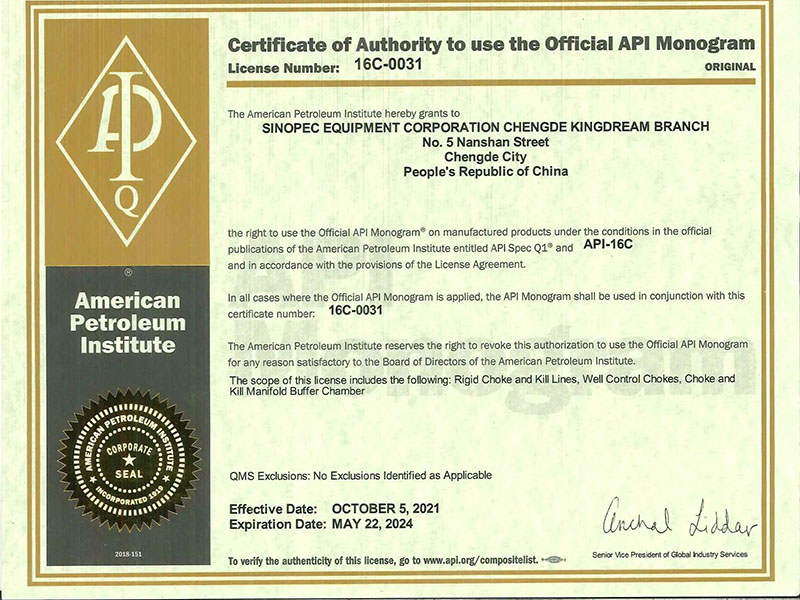

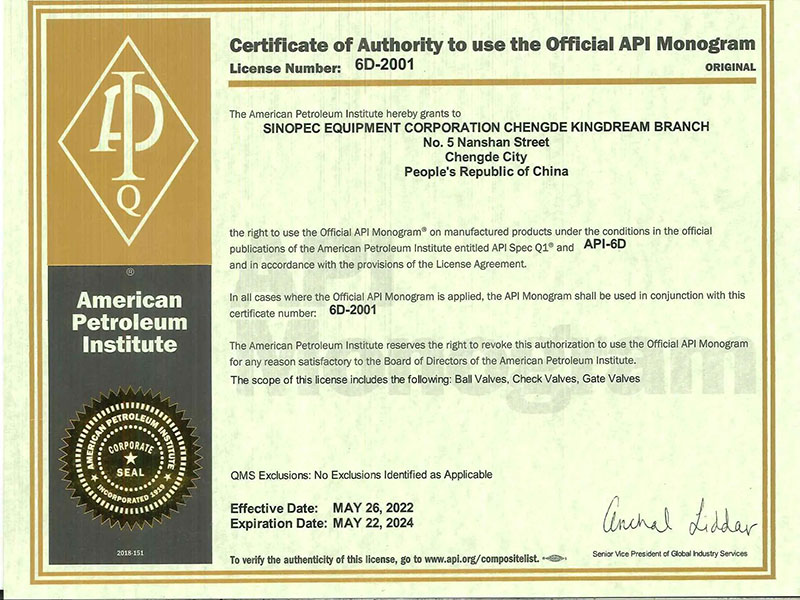

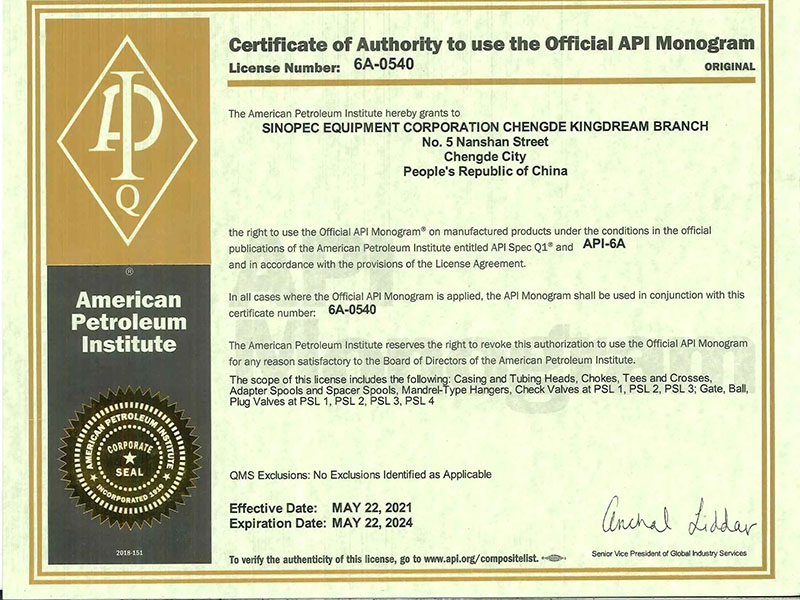

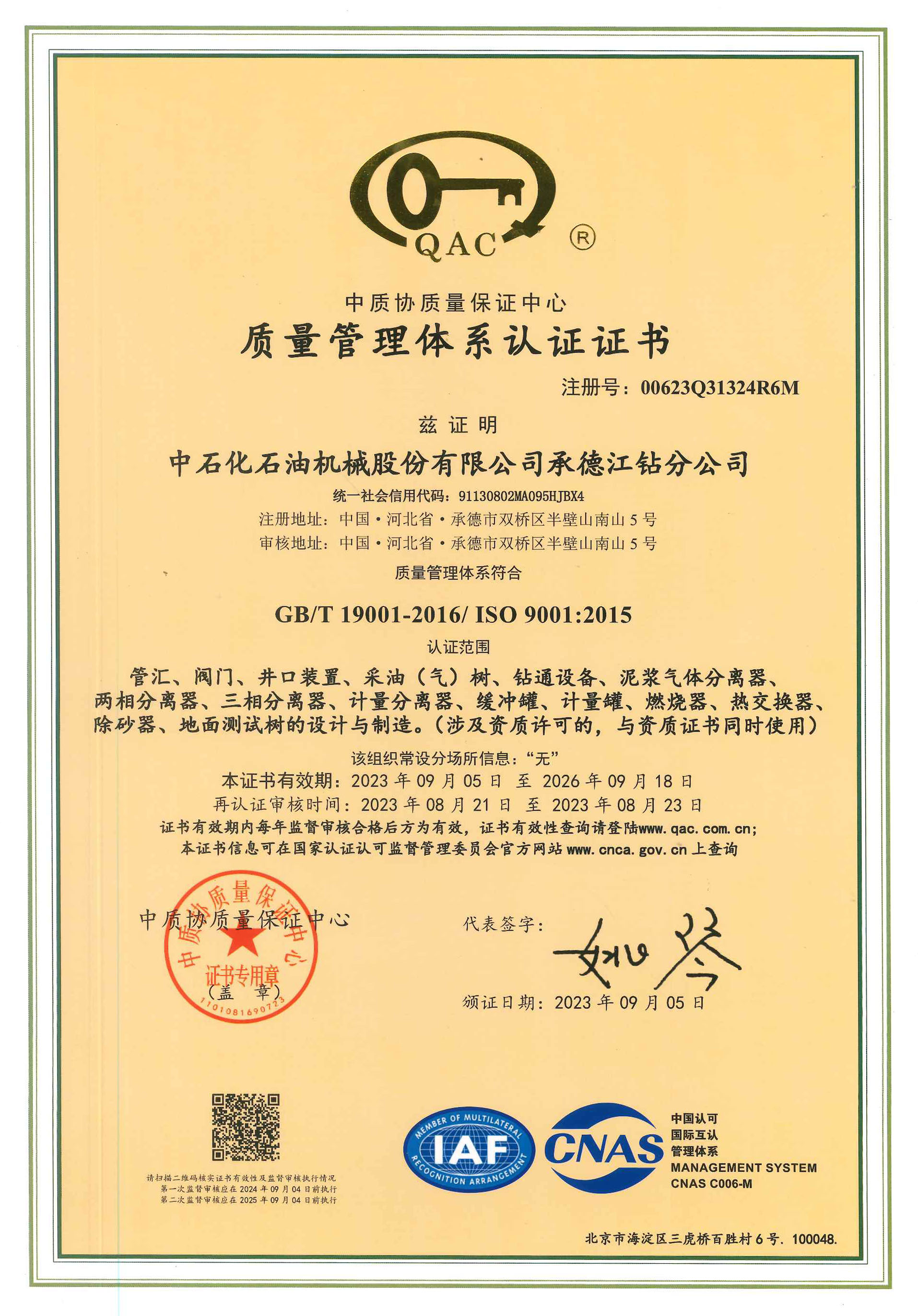

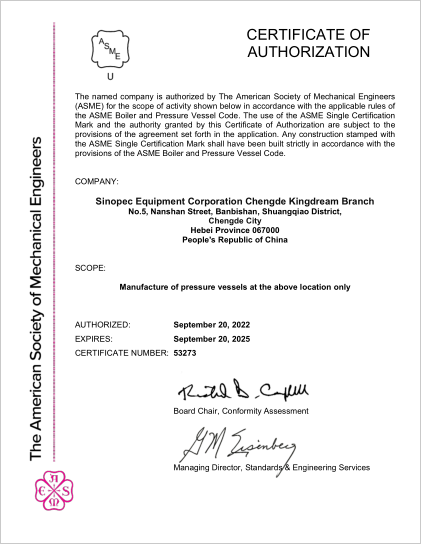

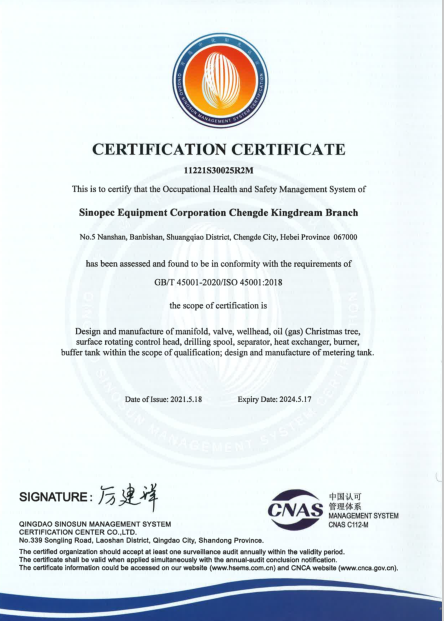

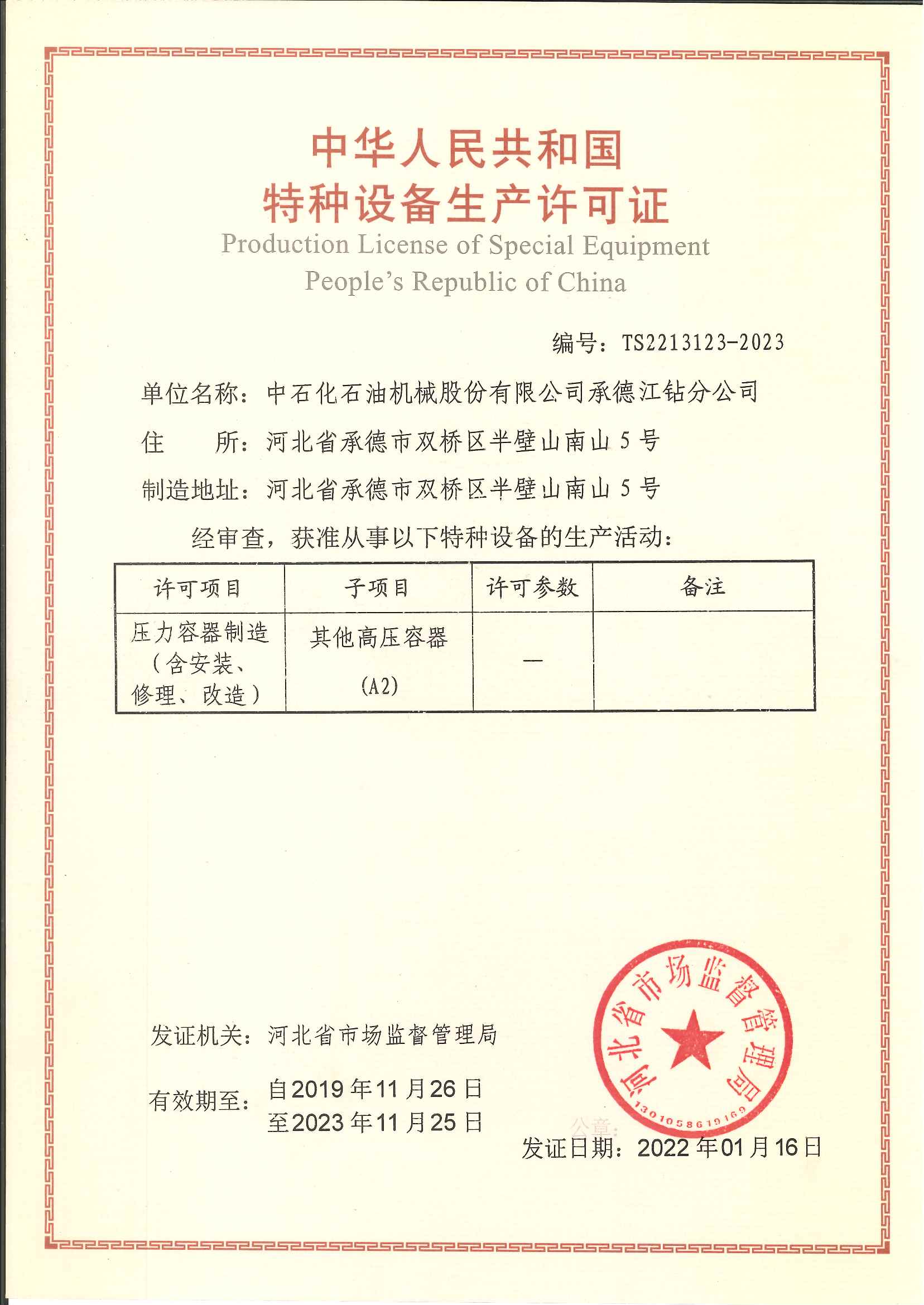

The products are designed and manufactured according to API Spec16C and 6A.

All kinds of valves are made of corrosion-resistant and erosion resistant materials, with good sealing performance, safety and reliability.

Our kill manifolds are expertly designed and rugged to withstand the extreme pressures and harsh conditions encountered in the oil and gas industry. Precision machined and high-grade materials, our kill manifolds offer superior strength and corrosion resistance, making them an indispensable asset for well control operations.

Designed for easy installation and operation, our kill manifolds are user-friendly and require minimal maintenance, saving customers time and resources. Whether drilling operations are onshore or offshore, our kill manifolds offer the flexibility and adaptability to meet our customers' diverse needs.

Safety is paramount in the oil and gas industry, and our kill manifolds are engineered to meet the highest safety standards. With reliable and fail-safe features, it provides operators with peace of mind and ensures the protection of personnel and equipment during well control operations. Our kill manifolds are designed to provide precise and controlled fluid management, reducing the risk of well control incidents and minimizing environmental impact.

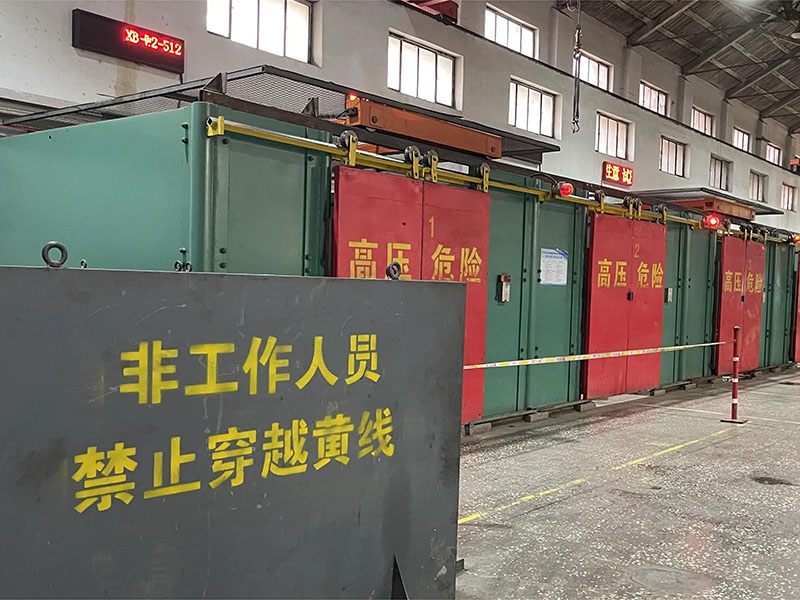

1, Pressure testing

2, Sealing testing

3, ICAS, CMA,CNAS third-part service