Understanding the Functions of Medium Pressure Well Manifolds in Well Control Equipment

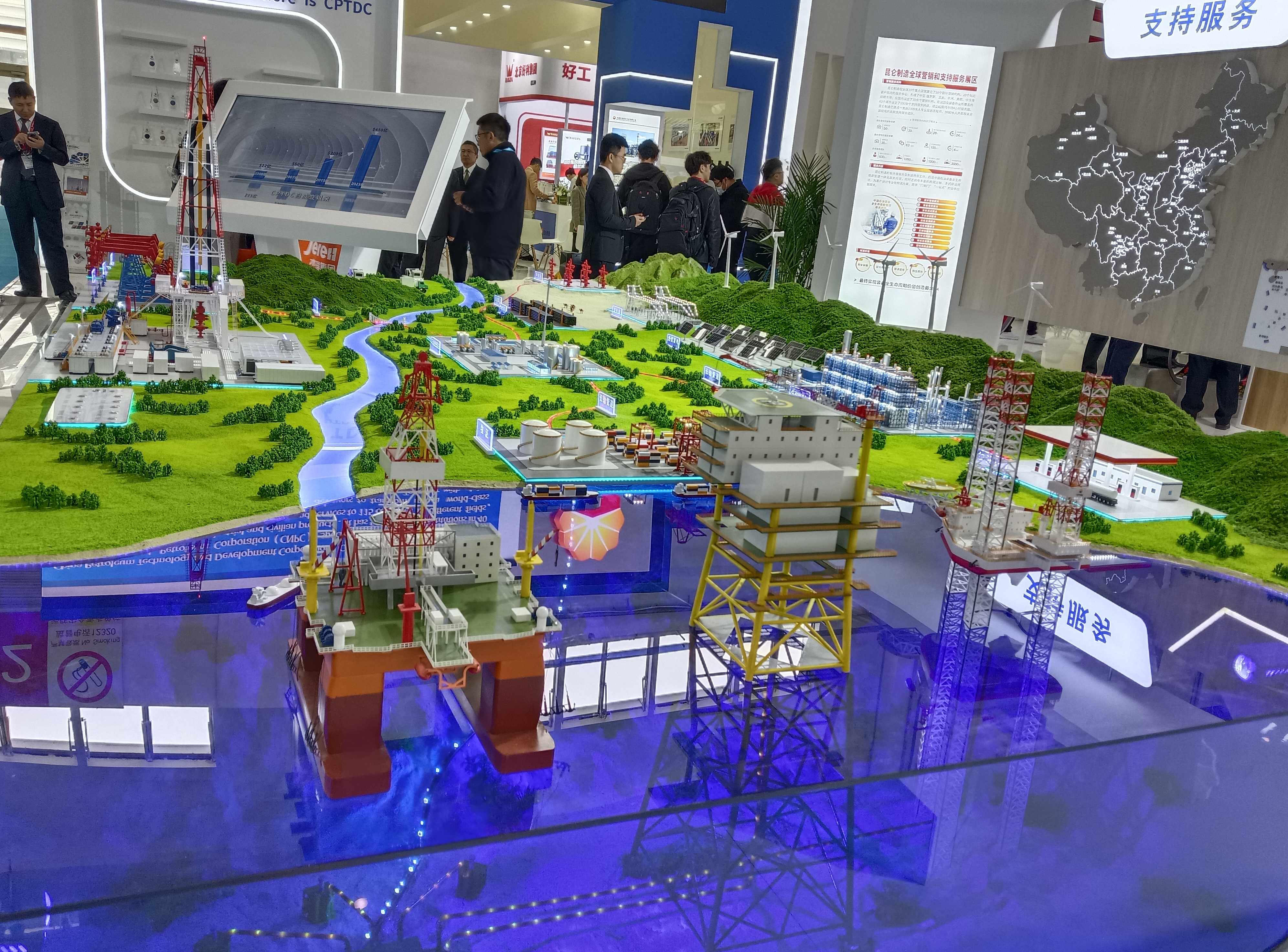

In the oil and gas industry, ensuring the safety and integrity of drilling operations is critical. Well control equipment is a key component in this process, providing the means to manage pressure and fluids within the wellbore. The kill manifold is an important part of the well control equipment and plays a vital role in maintaining control and preventing potential blowouts. In this blog, we’ll take a closer look at the functions of a kill manifold and its importance in well control operations.

The kill manifold is a key piece of equipment in well control used to manage pressure levels during drilling operations. It is used as a control system designed to direct and control fluid flow within the wellbore. The primary function of a kill manifold is to provide a means of injecting heavy fluids, such as drilling mud, into the well to control and suppress the flow of hydrocarbons.

During drilling operations, unexpected pressure inflows or kicks can occur, resulting in the uncontrolled release of formation fluids such as oil, gas, or water. In this case, a kill manifold is used to shut down the well quickly and efficiently, preventing the situation from escalating into a blowout. Injecting heavy fluids into the well through a kill manifold balances and controls pressure, ultimately restoring stability and preventing potential hazards.

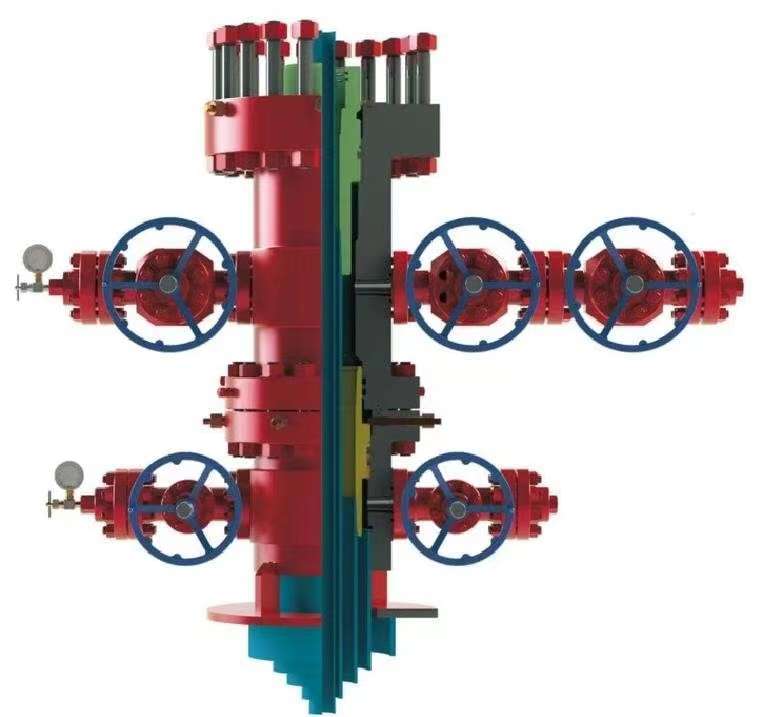

Kill manifolds are often equipped with valves, chokes and instrumentation to regulate fluid flow and monitor pressure levels. These components work together to accurately control the injection of fluid into the well, ensuring that pressure remains within safe operating limits. In addition, kill manifolds are often integrated with choke tubes, which further enhances their ability to manage well control operations.

If a kick or pressure surge occurs in the wellbore, kill manifolds allow drill crews to react quickly and take the necessary steps to regain control. Kill manifolds play a key role in preventing potential blowouts and maintaining a safe drilling environment by effectively isolating the well and introducing heavy fluids to equalize pressure.

Additionally, the design and operation of kill manifolds adhere to strict industry standards and regulations to ensure their reliability and effectiveness in well control scenarios. Regular inspection, maintenance, and testing of the kill manifold are essential practices to verify its functionality and readiness for deployment in an emergency.

In short, the kill manifold is an indispensable part of the well control equipment and an important guarantee to prevent pressure fluctuations and kicks during drilling operations. It quickly and effectively controls pressure levels within the wellbore, helping to prevent potential blowouts and maintain a safe drilling environment. Understanding the function and importance of the kill manifold is critical for all personnel involved in well control operations, emphasizing the importance of this critical component in ensuring safety and operational integrity.