What's The Inner Workings of Drilling Equipment Valves: Maintaining Control and Safety

Introduce:

In the complex world of drilling equipment, multiple critical components work seamlessly together to ensure smooth operation. Among them, valves play a vital role in regulating fluid flow, maintaining pressure, and even controlling emergency situations. This blog will take an in-depth look at the mechanics and function of valves, with a special emphasis on their importance in wellheads and well control.

Valves in drilling equipment:

A valve is a device used to control the flow of fluid, gas or slurry. In drilling equipment, they are critical for regulating the flow of drilling mud, a specialized liquid that aids in drilling operations. These valves are exposed to extreme pressures, high temperatures and corrosive substances; therefore, they must be durable, reliable and resistant to wear and tear.

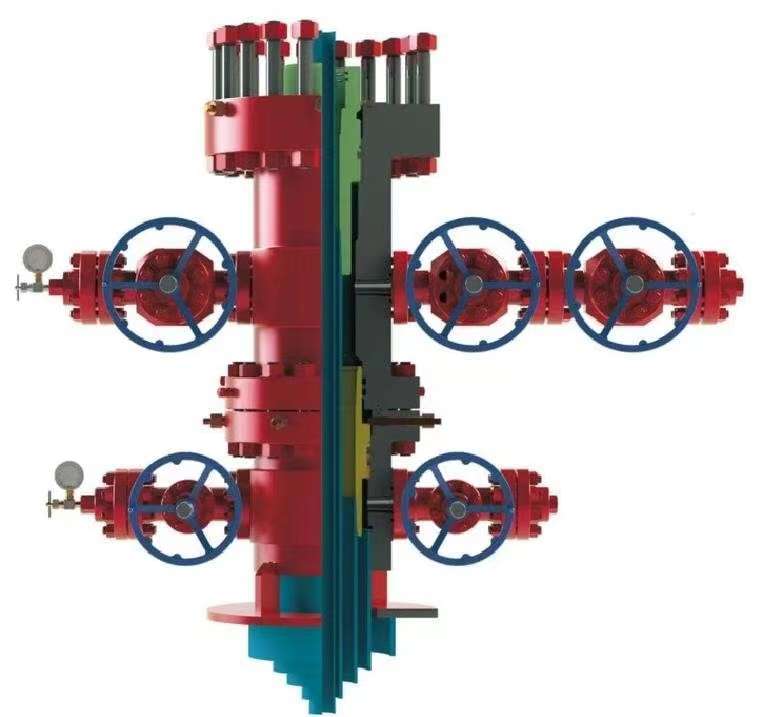

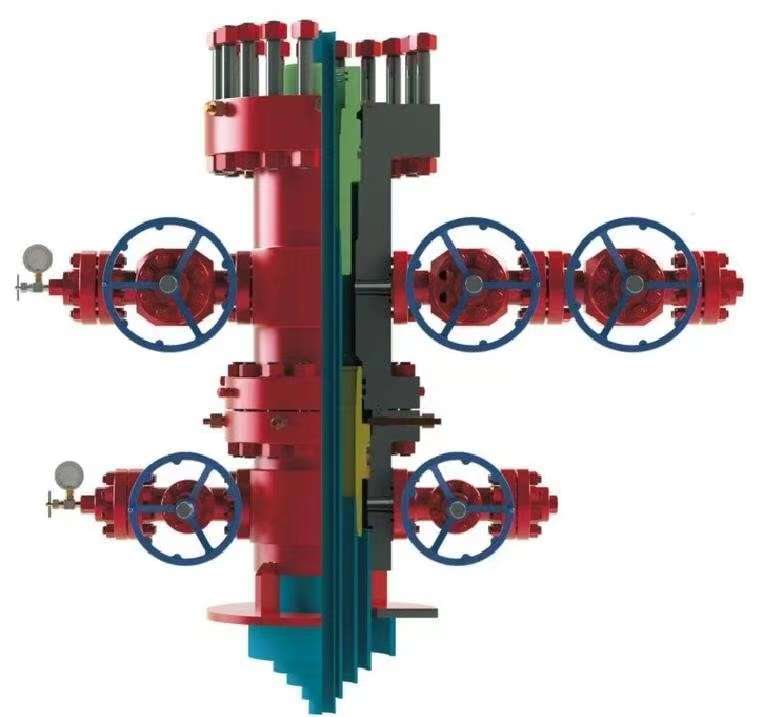

Wellhead and valves:

Wellhead devices are an important part of the surface of an oil or gas well and provide the necessary pressure control while drilling. At the wellhead, valves play a vital role in maintaining control and preventing catastrophic blowouts or uncontrolled releases of hydrocarbons. Two types of valves commonly used in wellheads are "gate valves" and "throttle valves."

1. Gate valve:

A gate valve is a linear motion valve that opens by lifting the gate out of the fluid flow path. It provides effective on/off control of the well and is typically used during the drilling phase. Gate valves are designed to withstand high pressures and prevent fluid backflow. They are usually located below the wellhead and act as a barrier against any unexpected surges.

2. Throttle valve:

A choke valve, also known as a control valve, helps restrict and control the flow of fluid through the wellhead. It can be operated in a variety of positions to maintain the required flow and pressure during drilling. This type of valve plays an important role in reducing possible well control incidents, suppressing excessive pressure, and preventing equipment failure.

Well Control and Valve Functions:

Well control is the process of maintaining pressure and fluid flow within safe limits during drilling operations. Here, the valve comes into play to accomplish two main functions:

1. Blowout preventer (BOP) valve:

BOP valves are considered the last line of defense against uncontrolled flow. These valves are installed above the wellhead, providing an extra level of safety. They block oil wells in emergencies, effectively preventing blowouts. Hydraulic actuators can quickly close the blowout preventer valve to isolate the well from surface equipment.

2. Annular blowout preventer valve:

Annular BOPs use flexible elastomeric seals to seal the space between the drill pipe and the wellbore. These valves help control pressure and are critical for well control operations, primarily during drilling and completion activities.

In conclusion:

Valves in drilling equipment, especially in wellheads and well control systems, play a critical role in preventing accidents, maintaining required pressure and controlling fluid flow. Understanding its functionality and ensuring its reliability are critical to safe and efficient drilling operations. As technology continues to advance, valves will undoubtedly continue to evolve to provide greater levels of control, safety and environmental protection.