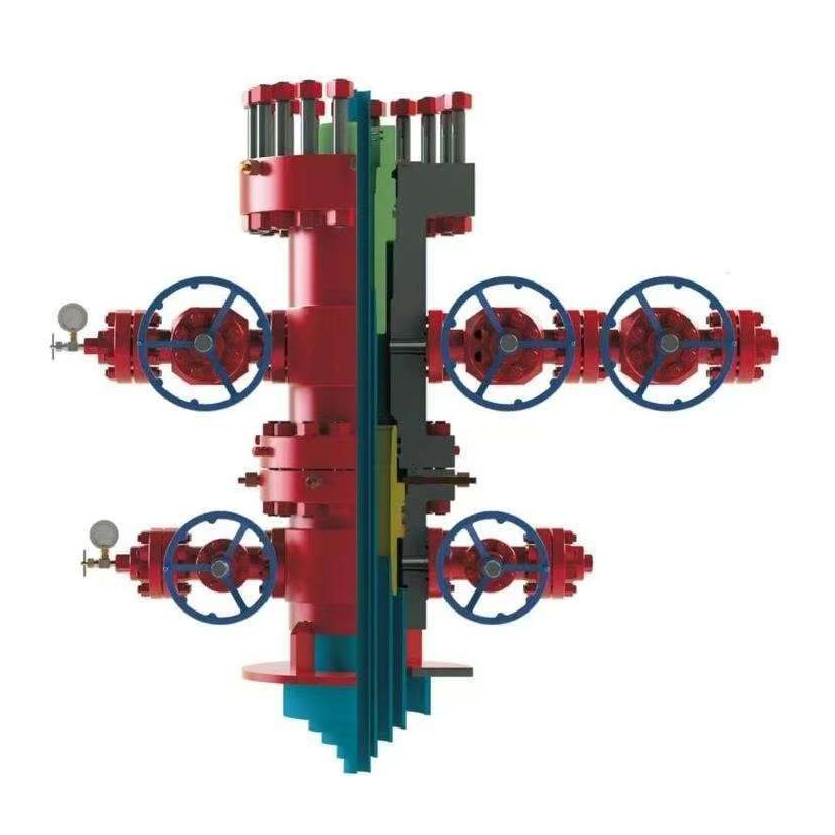

Casing head assembly for Wellhead equipment

product Description

●Straight seat design

The 45° shoulder is designed for high load performance

●Side outlet connection type

Thread side outlet of pipeline

Threaded flange side outlet with VR plug

●Interchangeability of casing hanger

The casing hanger is designed as standard shape, and the slip type casing hanger and mandrel type casing hanger are interchangeable

●Casing head

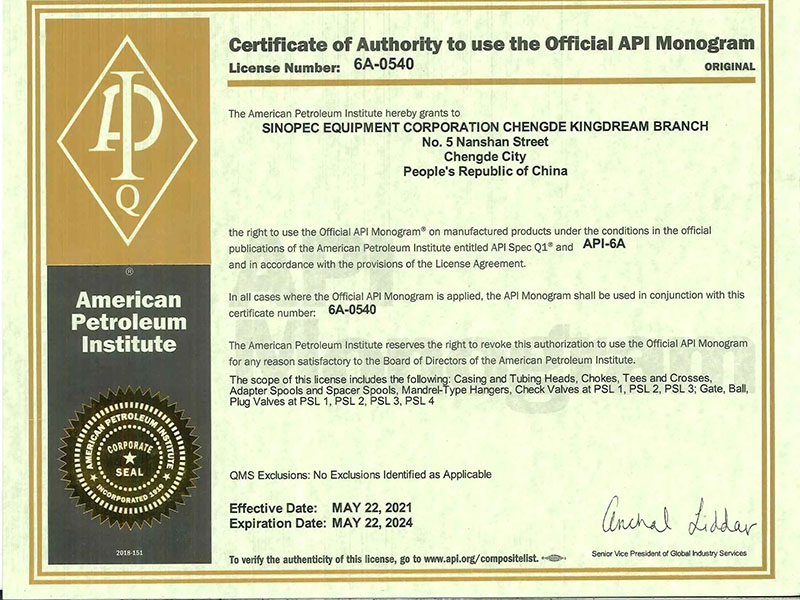

The casing head and casing cross are designed according to the standard and can be applied to all types of slip type and mandrel type casing hanger

●Secondary seal

The secondary seals with various structures are designed at the bottom, which can be installed on site by injection or non-injection according to different structure types, so as to achieve the sealing effect

●Connection type between casing head and surface casing

Bottom thread type, bottom welding type, bottom slip type

Introducing our top-of-the-line casing head assemblies designed to meet the needs of the oil and gas industry. This important piece of equipment plays a vital role in the drilling process and is the connection point between the casing and the wellhead. Our components are designed to withstand the extreme pressures and temperatures found in drilling operations, ensuring reliable performance and safety on site.

Our casing head assemblies are constructed from premium materials, including heavy-duty steel and corrosion-resistant alloys, to provide long-lasting durability and resiliency in the most challenging environments. The design incorporates advanced engineering principles to provide maximum strength and stability while minimizing weight and footprint for easy handling and installation.

The assembly features precision machined threads and seals that ensure a secure, leak-free connection between the casing and wellhead, preventing costly downtime and environmental hazards. Additionally, our innovative design allows for easy access and maintenance, reducing service time and operational disruption.

Our casing head assemblies are available in a variety of sizes and configurations to accommodate a variety of casing diameters and pressure ratings, making them suitable for a variety of drilling applications. Whether operating onshore or offshore, our components provide the versatility and performance needed to meet the specific requirements of each project.

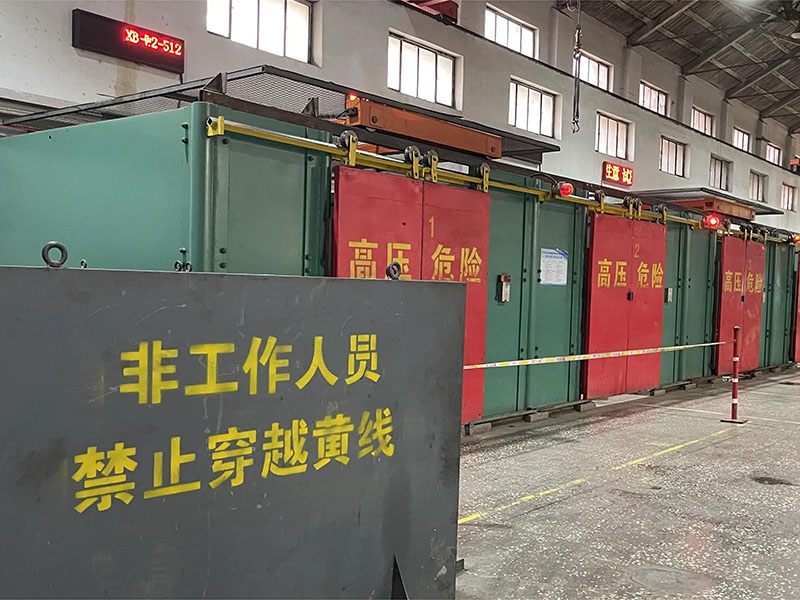

1, Pressure testing

2, Sealing testing

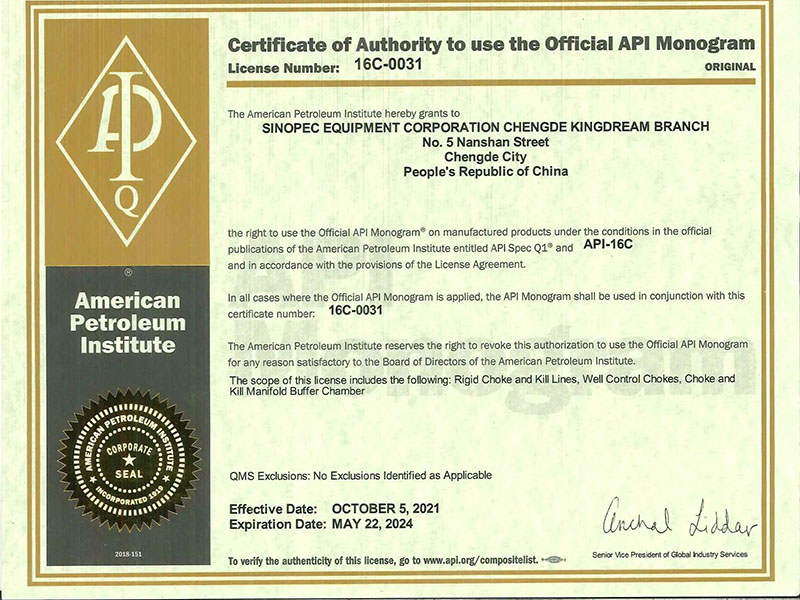

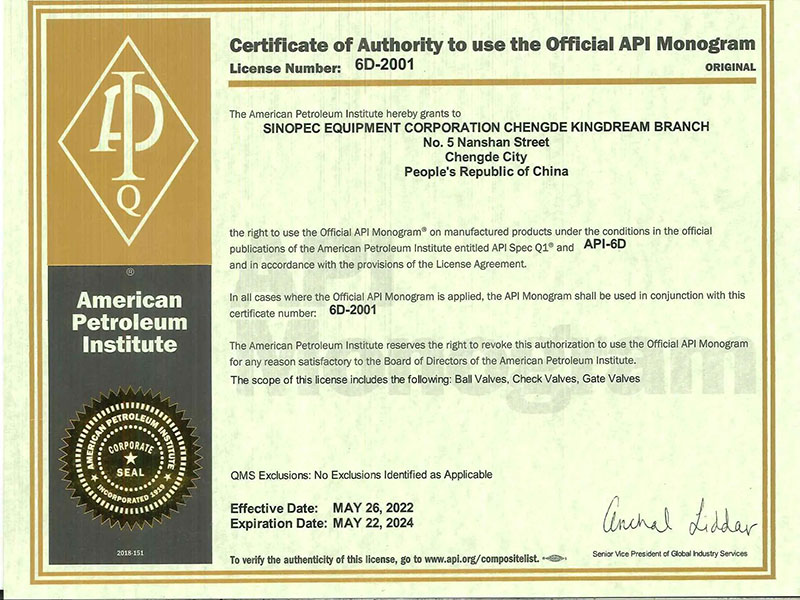

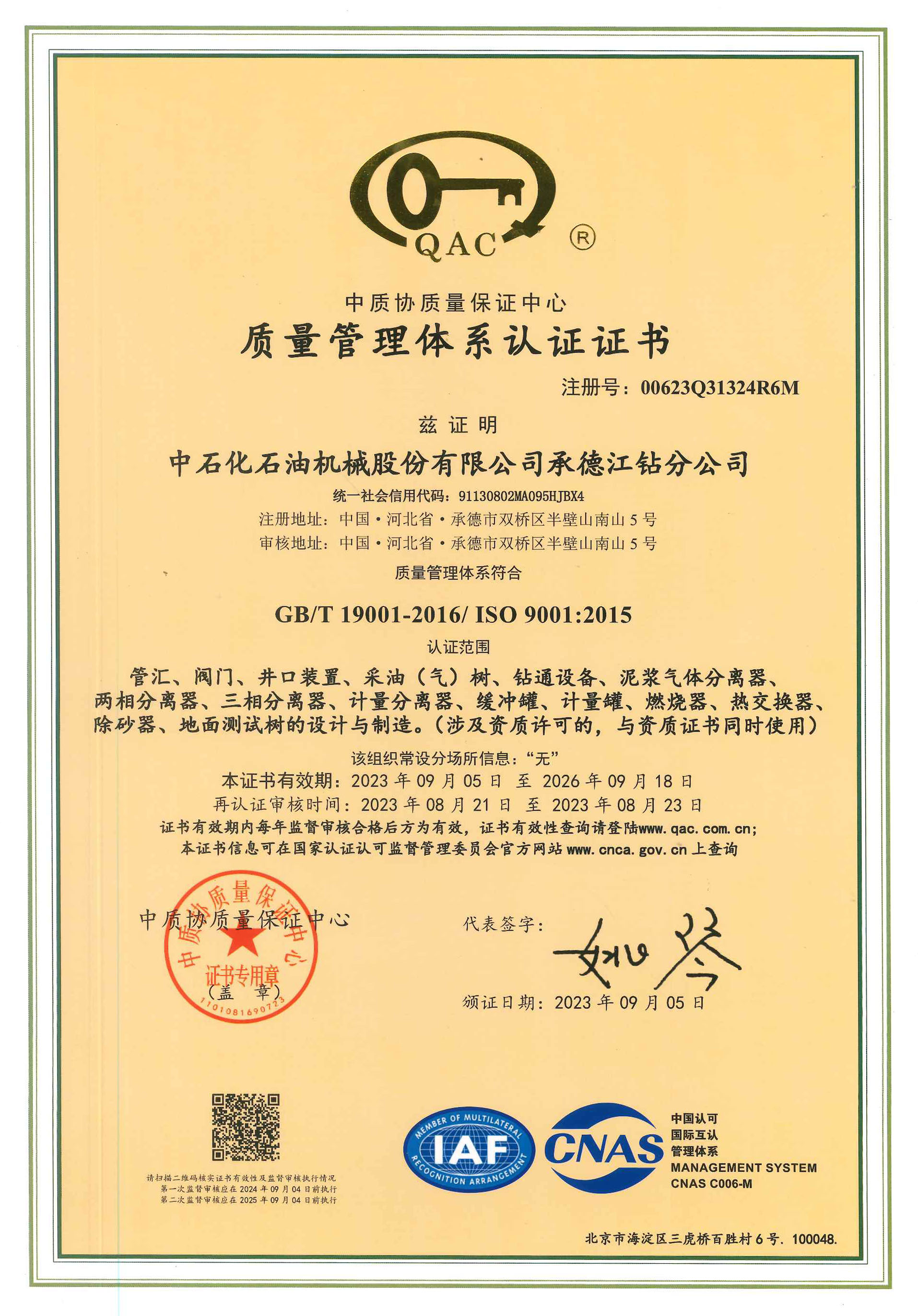

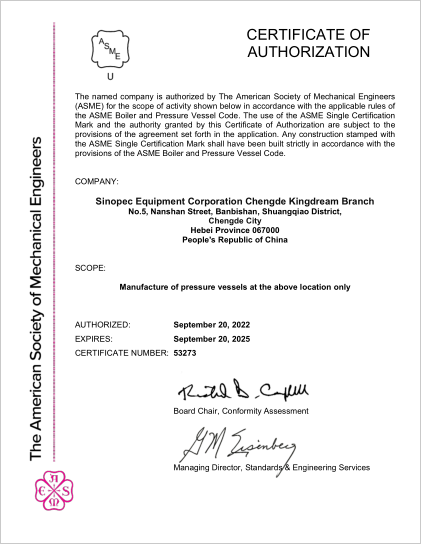

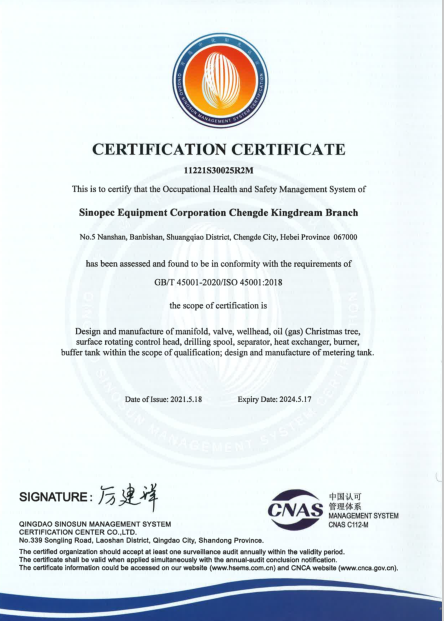

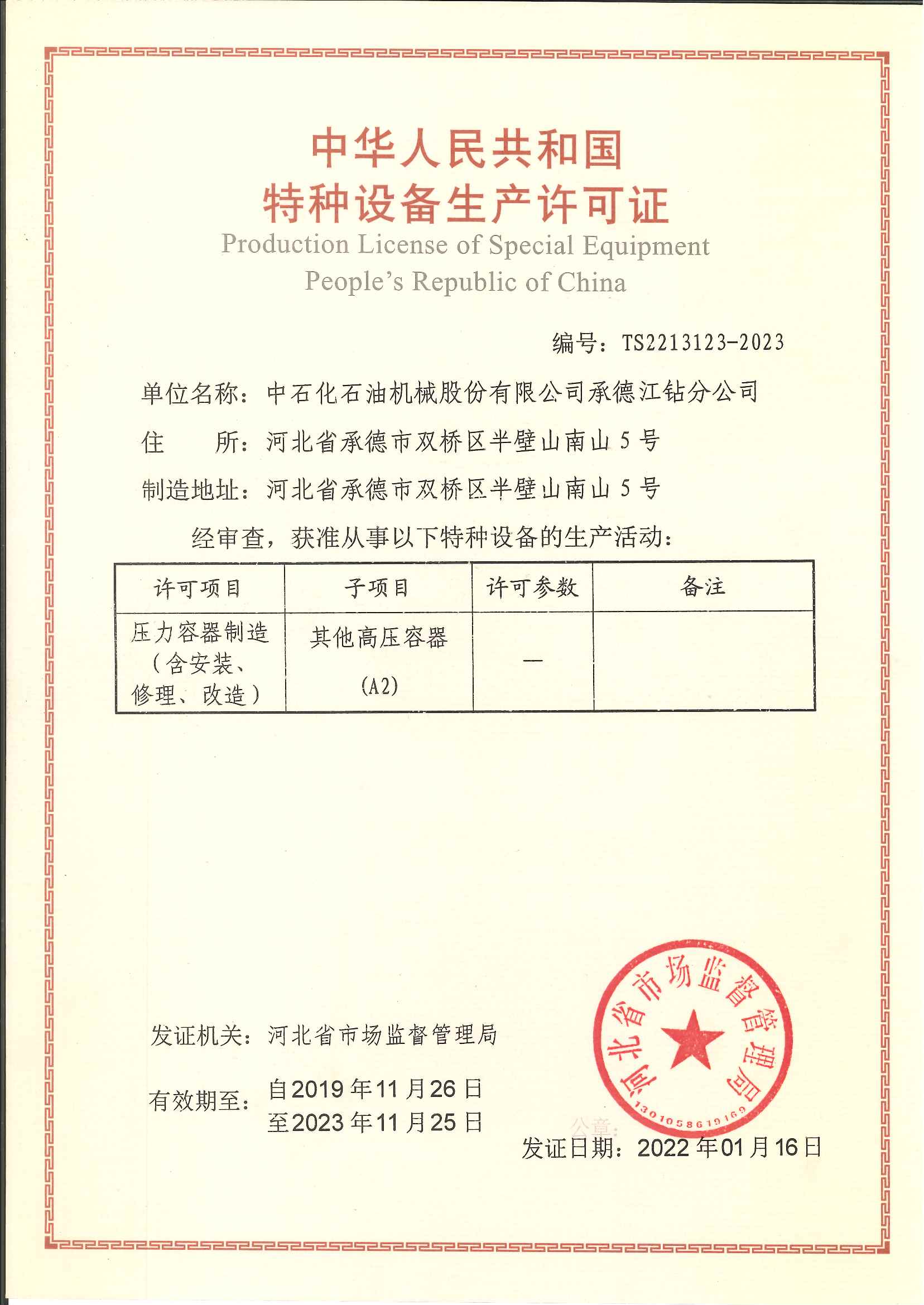

3, ICAS, CMA,CNAS third-part service