Scrap trapper or Chip catcher of wellhead and well control assembly Double Channel Debris for Drilling and Grinding Bridge Plug

product Description

Scrap trapper

The scrap trapper (Double debris collection device for drilling and grinding bridge plug) also called Chip catcher, is forged with low alloy steel, the gate valve is forged with integral die, and the internal liquid and sand passage of manifold is overlaid to improve the erosion resistance,

ensure the reuse of multiple wells, and realize the continuous blowout and continuous collection of drilling and grinding debris when replacing the nozzle of drilling and grinding bridge plug.

Main technical parameters of Scrap trapper/chip catcher

Working pressure: 35MPa (5000Psi)-105MPa(15000Psi)

Applicable media: oil, mud, hydrogen sulfide, bridge plug debris

Working temperature: P-U(-29C~121℃)

Product specification level: PSL3

Performance requirement: PR1

Material grade: EE

One of the main advantages of scrap collectors is their ease of installation and maintenance. Its compact size and user-friendly design allow it to be easily integrated into existing wellheads and control systems, while also allowing for quick and easy cleaning and maintenance as needed. Over time, this ultimately results in improved operational efficiencies and cost savings.

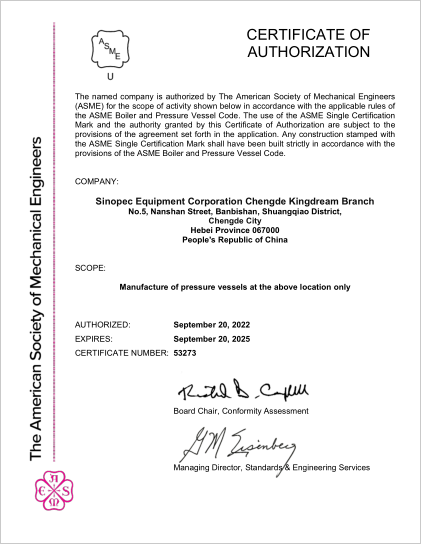

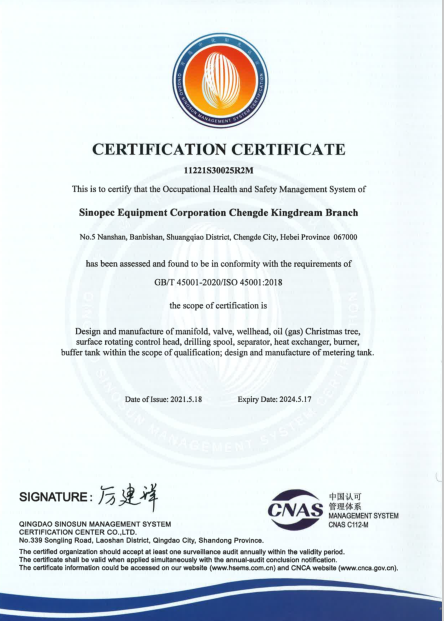

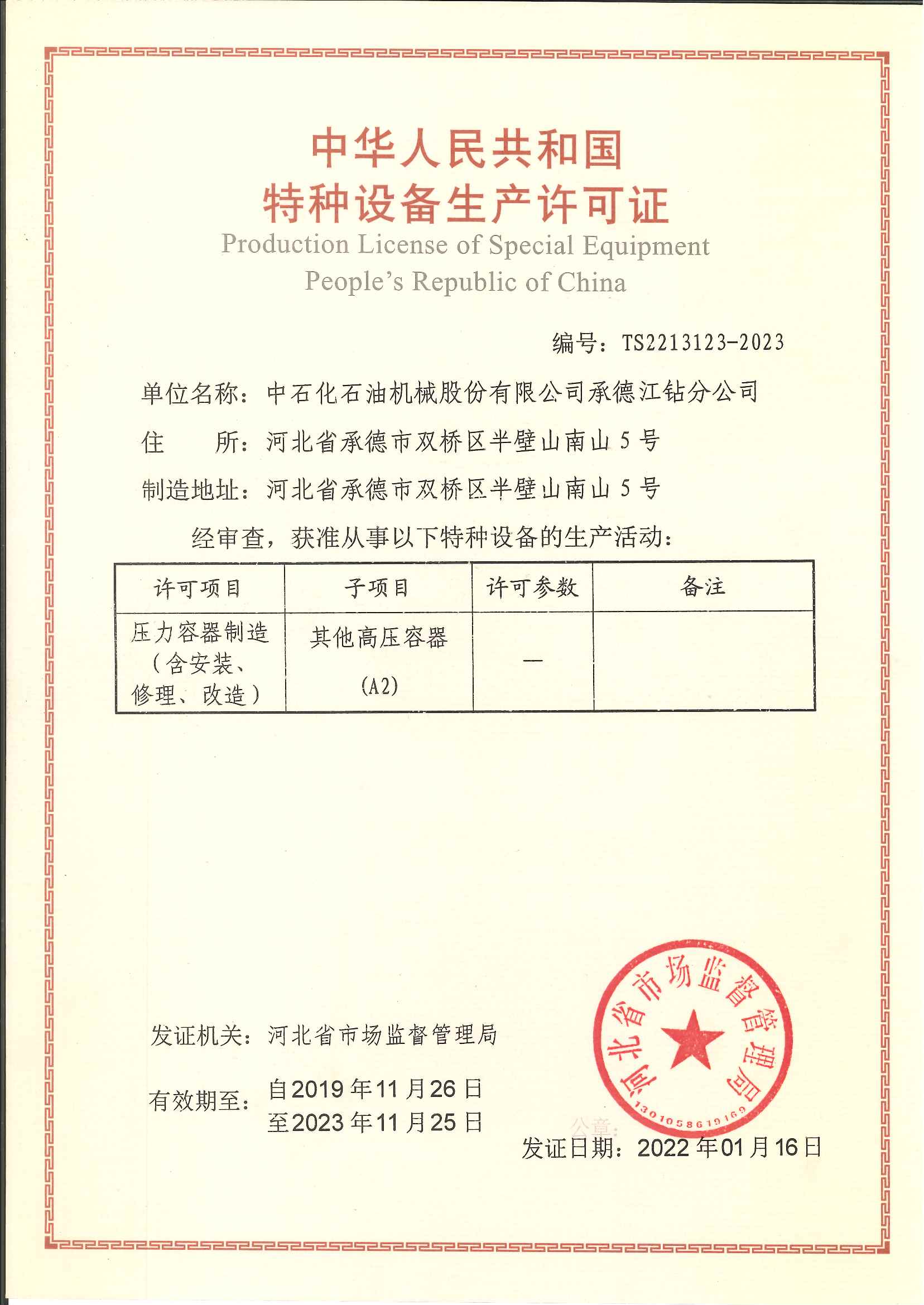

In addition to its functional advantages, the scrap trapper is designed to meet the highest industry quality and reliability standards. Made from high-quality materials and subject to rigorous testing and quality control measures, chip catcher is designed to withstand the harsh conditions and demands of drilling operations, ensuring long-lasting performance and peace of mind for our customers.

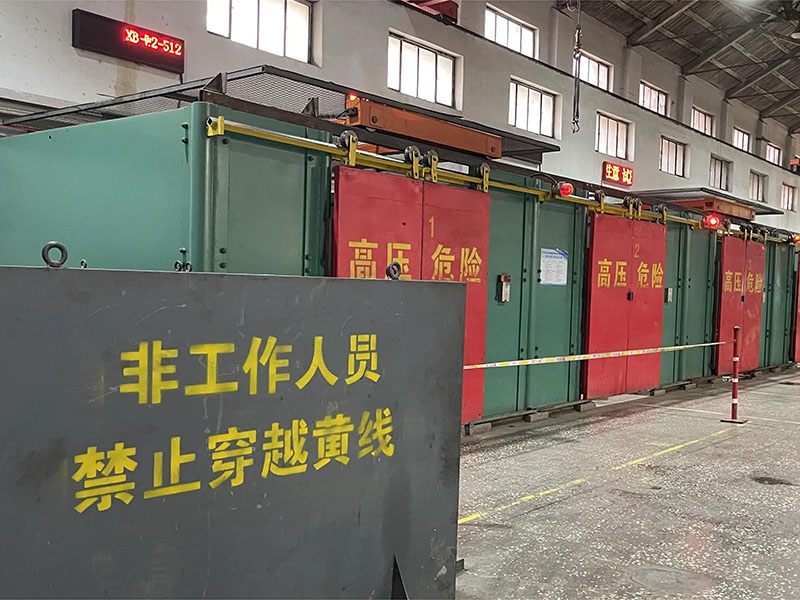

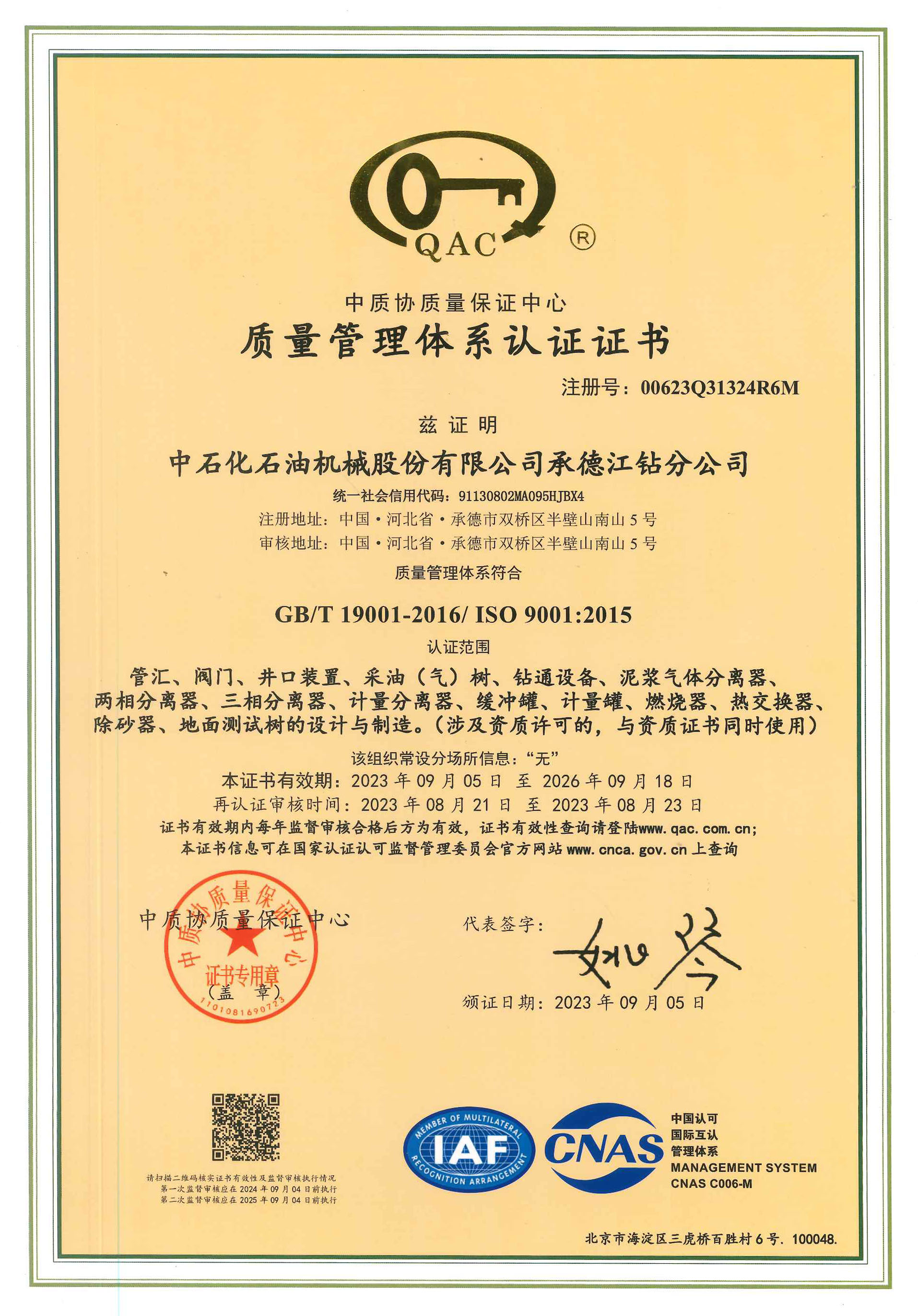

1,Pressure testing

2,Sealing testing

3,ICAS, CMA, CNAS third-part service

Wellhead equipment and Christmas tree could be used onshore and offshore, for oil and gas well