Three phase separator of oil and gas well

product Description

Main technical specifications of three phase separator:

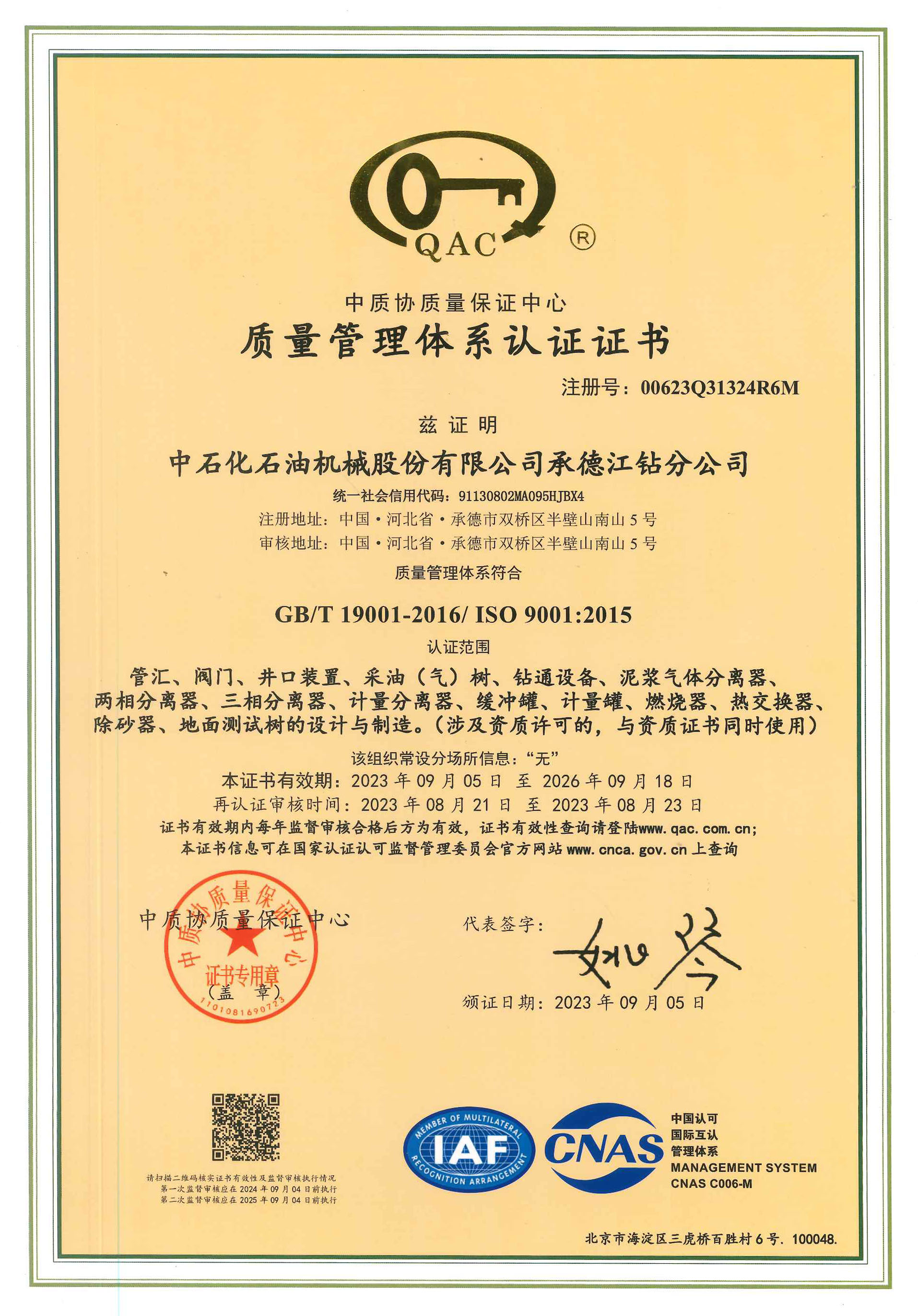

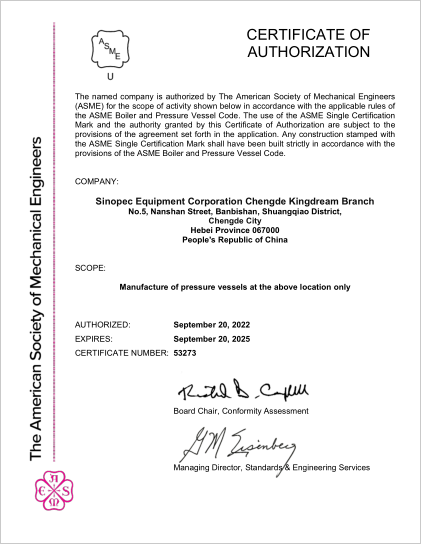

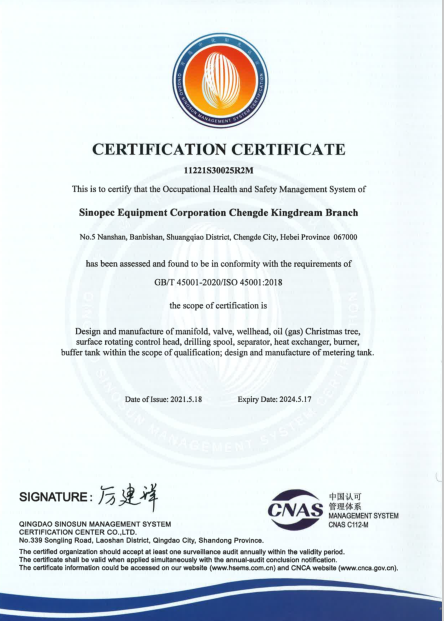

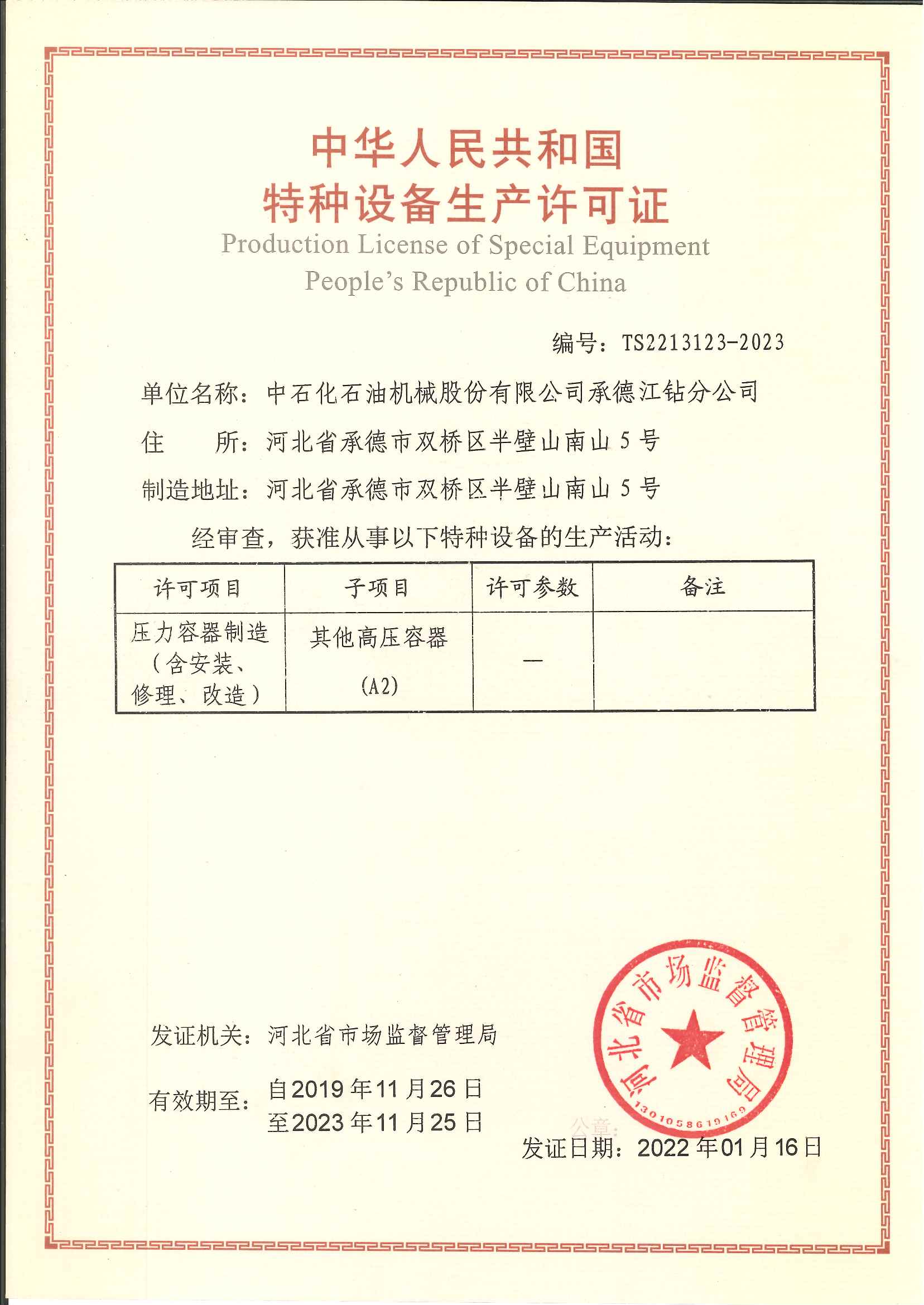

Standards: SY/T 0515-2014, GB/T 150.1-150.4-2011、ASMEⅧ-1

Design pressure: 0.1-15MPa

Design temperature: -40~121℃

Operating medium: natural gas, crude oil and water

Structure type: two-phase, three-phase

Three-Phase Separator of wellhead and well control equipment

When the oil and gas flow from the oil well enters the separator through the inlet pipeline of the separator, the oil and gas flow passes through the inlet energy absorber to complete the primary phase separation.

After the initial phase separation, the oil flow is buffered by the corrugated plate, and the mist is further removed from the flow, so that the residual droplets are removed.

The separated natural gas is discharged from the tank after passing through the anti-vortex fog catcher at the gas outlet, and enters the gas flow through the measuring orifice plate device and the pneumatic control valve.

The separated liquid is separated by gravity. There are oil and water outlets in front of and behind the oil separation plate. The oil and water flow out of the plate are measured by flow meters and then enter their respective processes.

The three-phase separator is mainly used for the separation of oil, water and gas. lt can also evaluate the daily output of crude oil and natural gas in oil wells through advanced metering instruments, and it is convenient for sampling and analyzing various components.

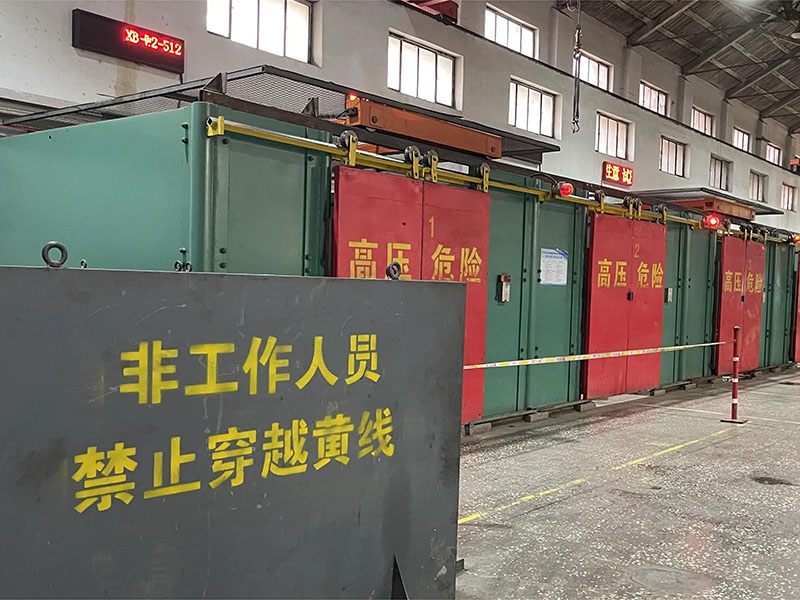

1,Pressure testing

2,Sealing testing

3,ICAS, CMA, CNAS third-part service

Wellhead equipment and Christmas tree could be used onshore and offshore, for oil and gas well