Chemical injection device of surface test products

product Description

The chemical injection device is used to inject antifreeze such as methanol or ethylene glycol into the fluid upstream of the test choke manifold, so as to prevent the formation liquid from blocking the nozzle due to the pressure drop, which will cause the hydrate to freeze and increase the reliability of the surface test system and the pressure drop range of the upstream and downstream of the nozzle.

The chemical reagent is injected through the chemical reagent injection port on the data head.

Main technical parameters

Working medium: methanol or glycol

Tank capacity: 37.1L (10 US gal)

Injection capability: 0.01-0.19m³/h(0.17-3.17L/min)

Air pressure: 0.69MPa(100Psi)

Injection pressure: 70MPa(10000Psi), 105MPa(15000Psi)

Our chemical injection equipment is designed to meet the stringent requirements of the oil and gas industry, providing precision and accuracy in the chemical injection process. It is equipped with advanced features that integrate seamlessly with wellhead and control surface systems for smooth, controlled chemical injection.

This state-of-the-art equipment is designed for durability and reliability, making it suitable for use in harsh and challenging operating environments. Its rugged construction ensures longevity and consistent performance, minimizing customer downtime and maintenance costs.

Chemical injection units are also equipped with safety devices to prevent overpressure and ensure safe handling of chemicals. This prioritizes operator well-being and equipment integrity, and complies with industry standards and regulations.

In addition, our products are designed with user-friendly interfaces and intuitive controls that make it easy to operate and monitor the injection process. This streamlines operator workflow and increases productivity during wellhead and control surface maintenance and testing procedures.

Our company is committed to providing quality products and excellent customer service. We work closely with our customers to understand their unique needs and provide customized solutions that meet their specific needs.

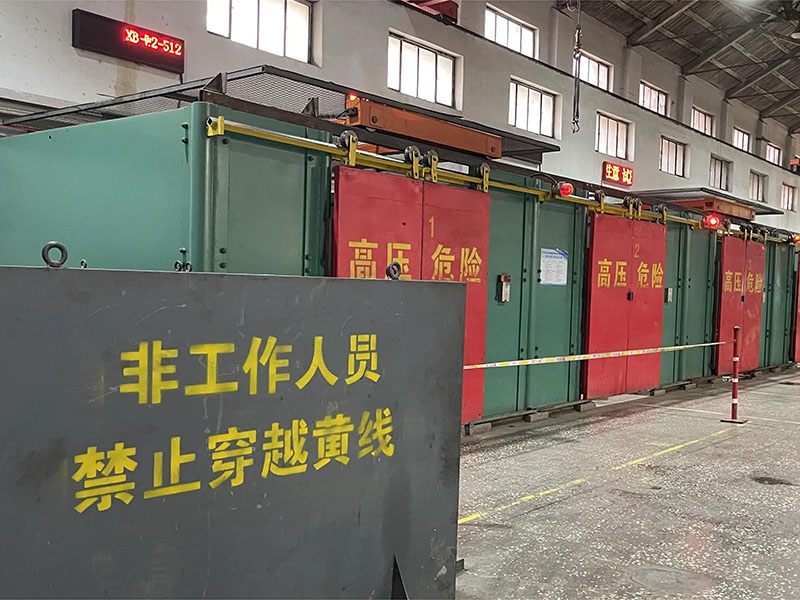

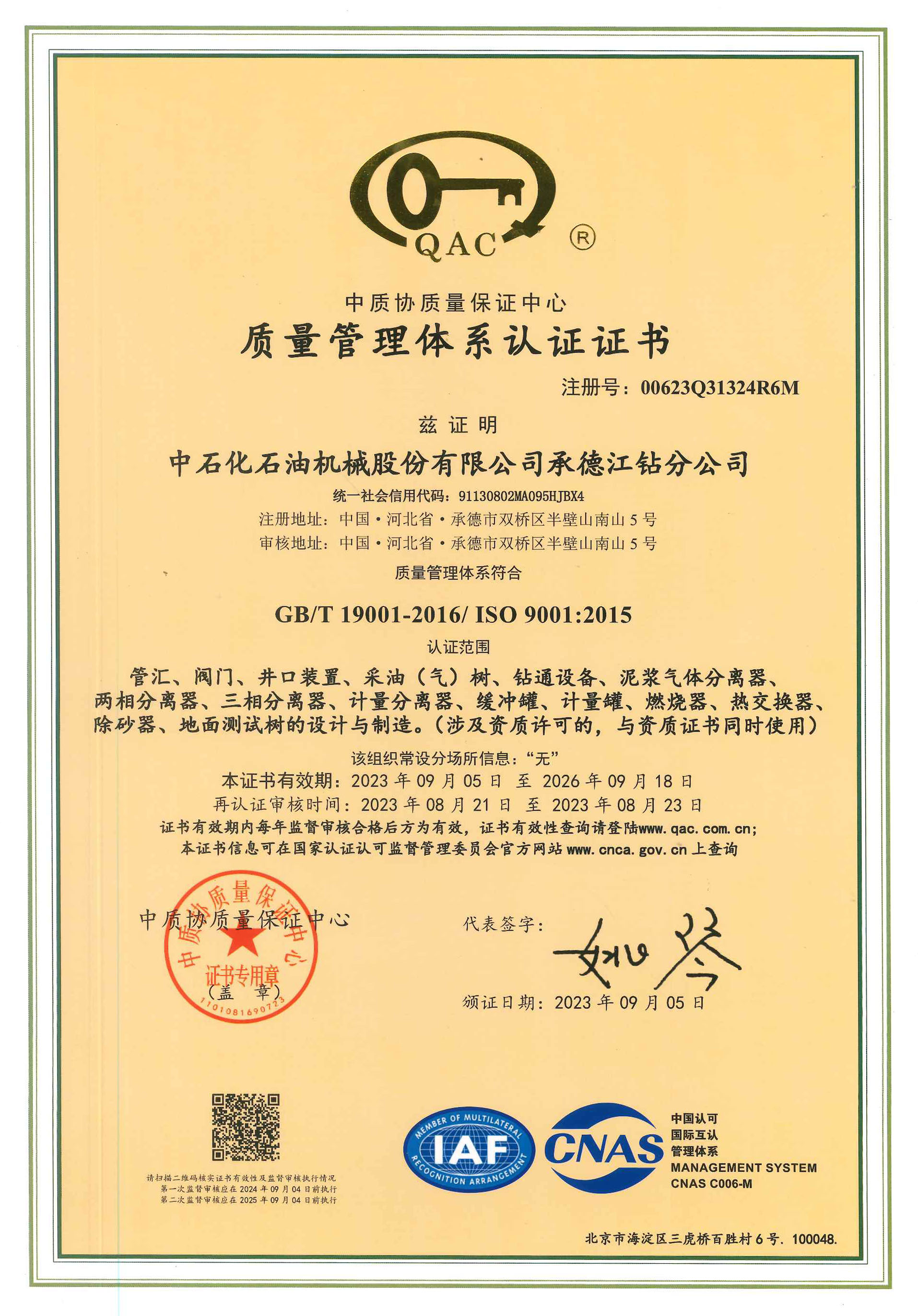

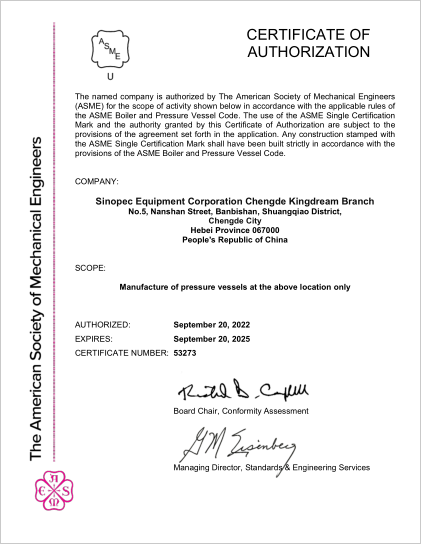

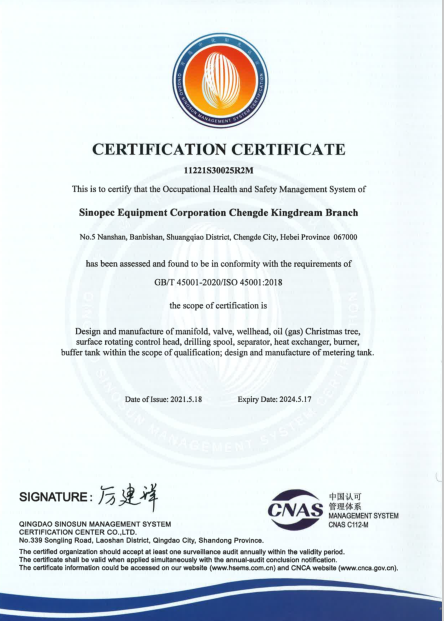

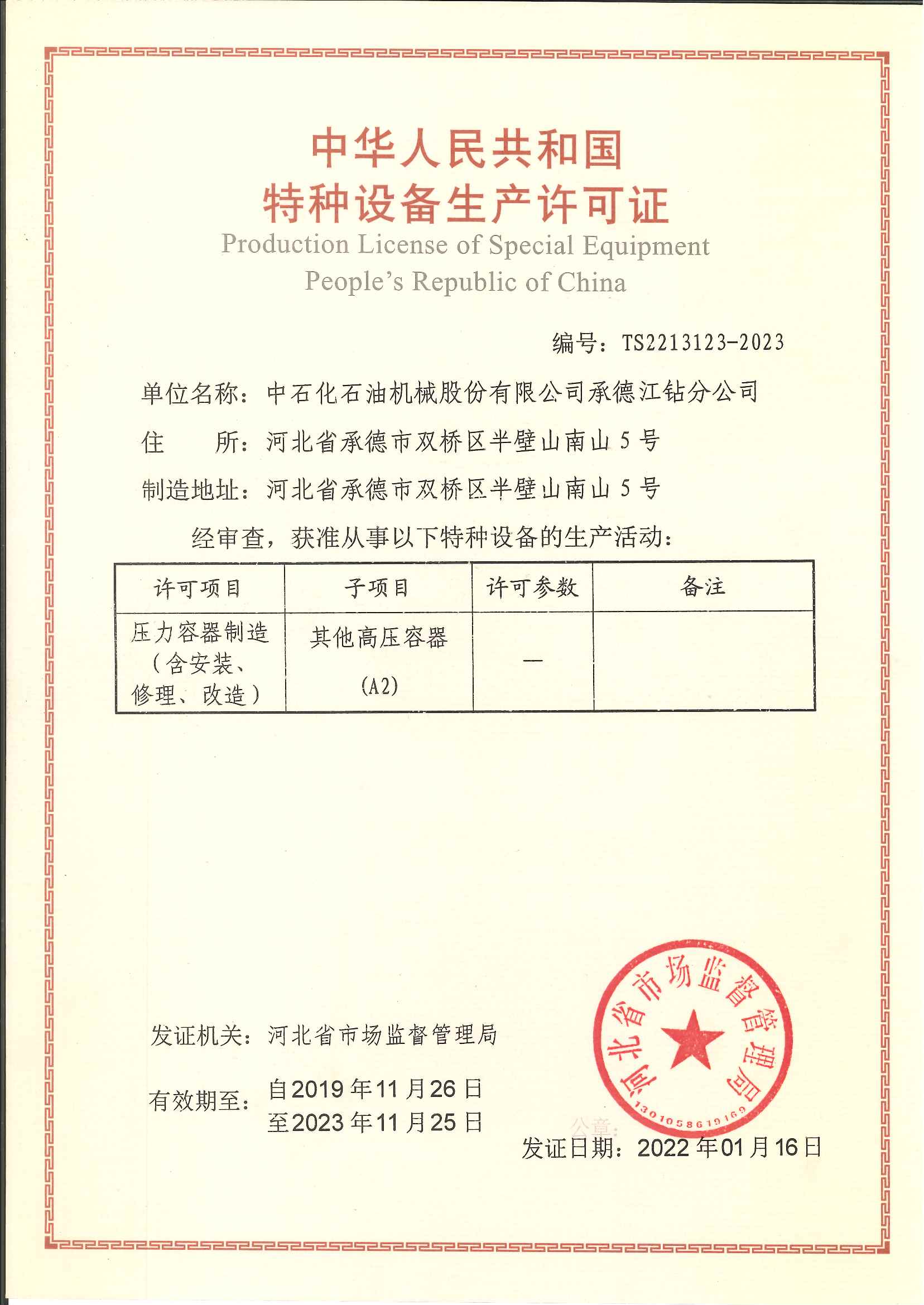

1,Pressure testing

2,Sealing testing

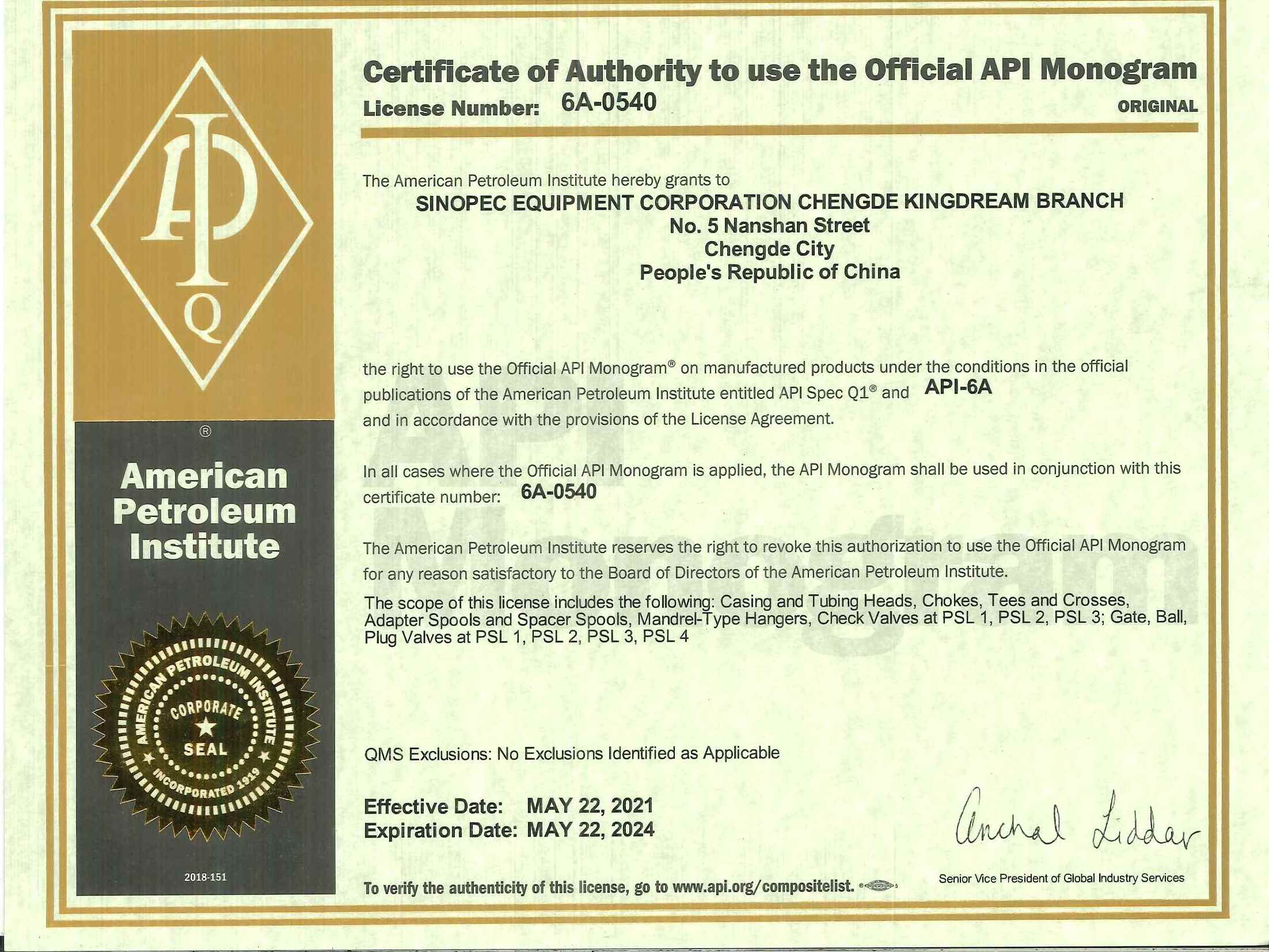

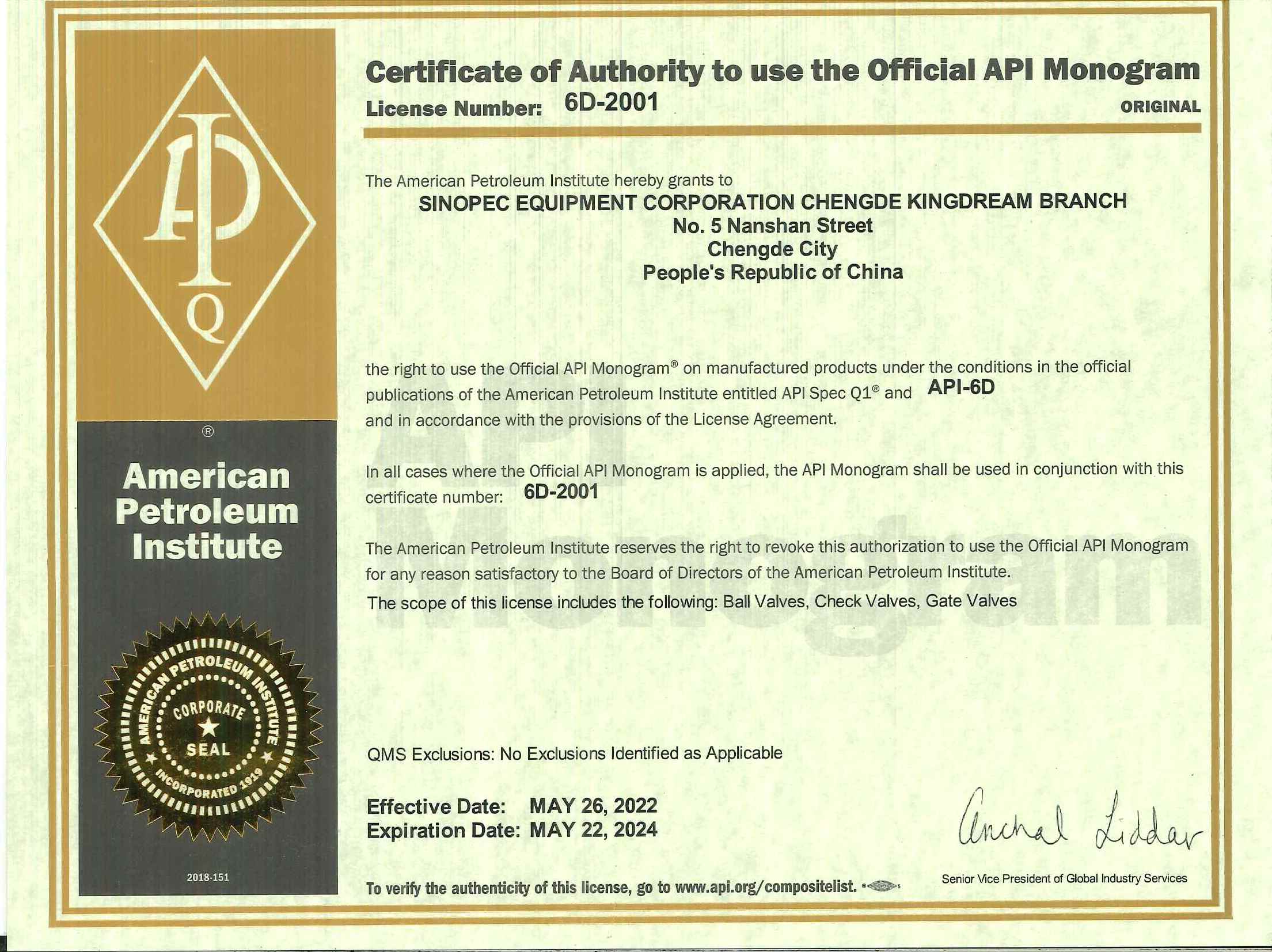

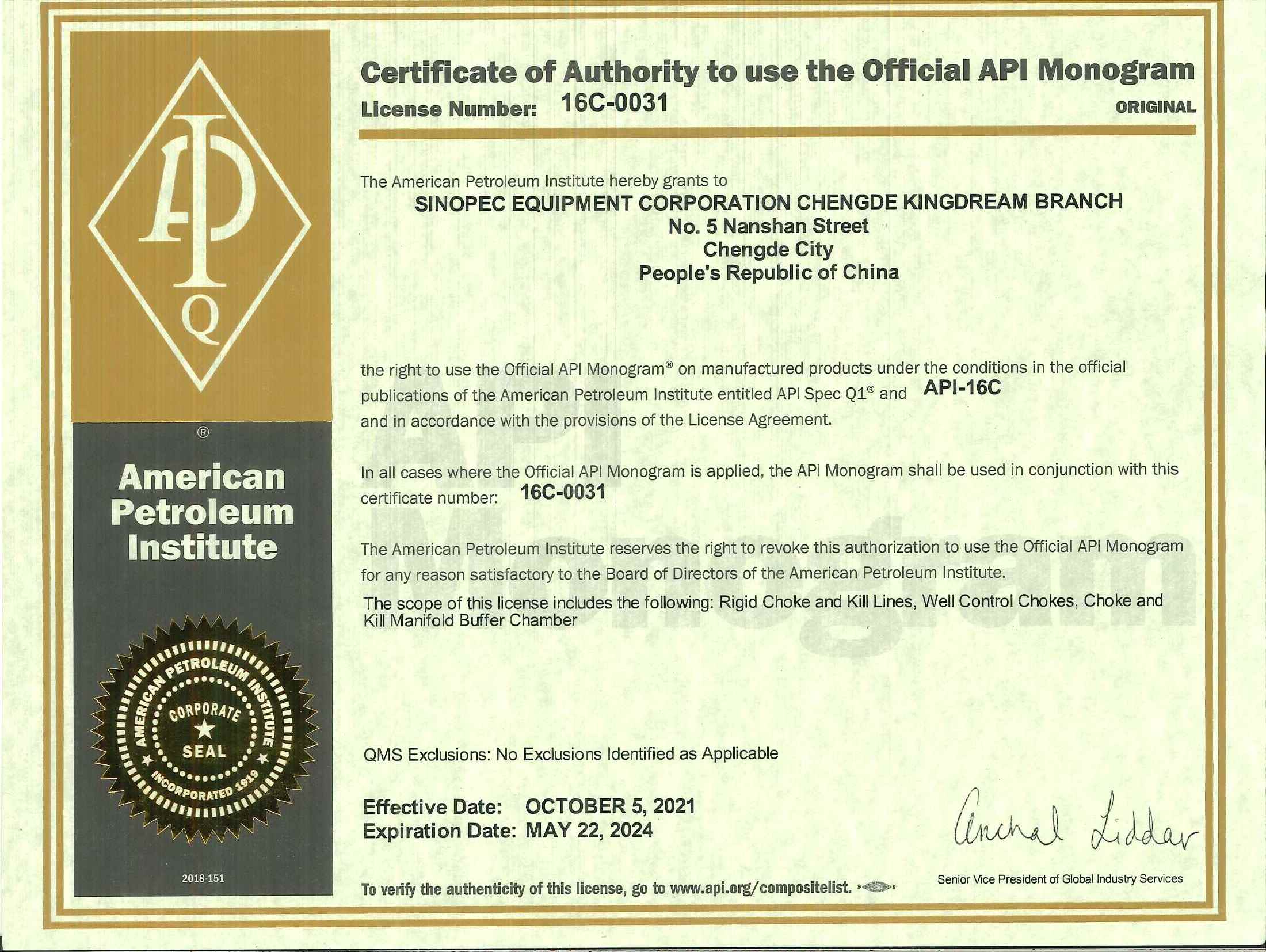

3,ICAS, CMA, CNAS third-part service

Wellhead equipment and Christmas tree could be used onshore and offshore, for oil and gas well